Harmer Modular 120 features a high performance

Stainless Steel modular channel system in a range of

depths with a choice of grating finishes to suit a variety

of internal drainage applications.

Applications

- Modular 120 is suitable for a wide range of applications, including School &

Leisure, Food Production & Processing, Commercial Kitchens, Breweries,

Retail and Chemical & Pharmaceutical.

- Off the shelf stocked product range.

- Designed to drain high volumes of effluent water.

Materials & Finishes

- Available as standard in grade 304 Stainless Steel and also available in

made to order 316 grade Stainless Steel.

- All Stainless Steel is fully pickle passivated to ensure a high quality

corrosion resistant drainage system.

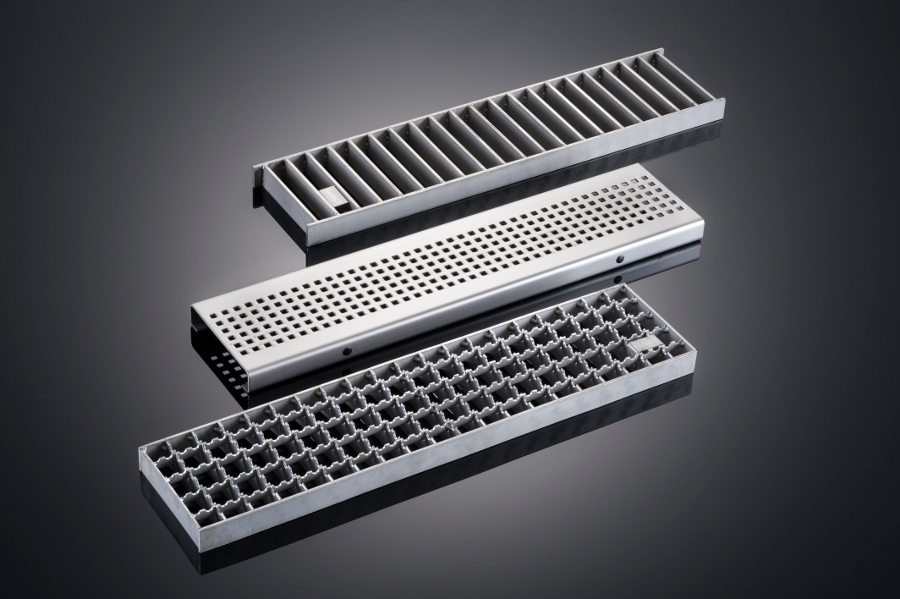

- Available in a choice of 3 grate finishes (Anti-Slip, Quattro & Ladder)

depending on design and load class requirements to BS EN:1433 - A15

(15kN) & C250 (250 kN)

- Supplied with a synthetic edge infill to all channel lengths to ensure a

resistance to high loads.

- Channels are available in 1000mm or 500mm lengths.

- Available in a range of sloping and level invert depths from 50-100mm.

Performance

- Fully tested and classified to BS EN:1433 - Drainage Channels for Vehicular

& Pedestrian Areas.

- Excellent corrosion resistance

Installation & Fixing

- Suitable for tiled, resin or concrete floor applications.

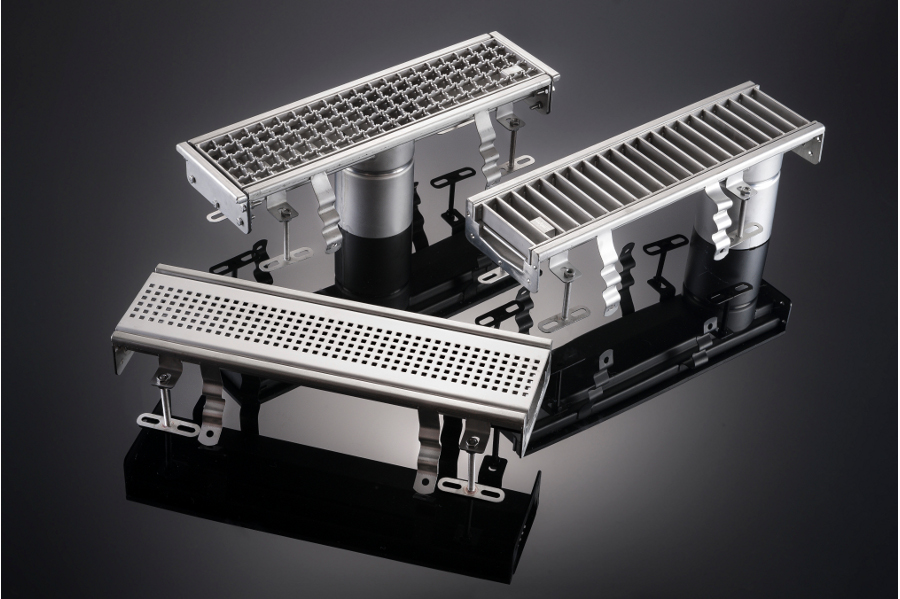

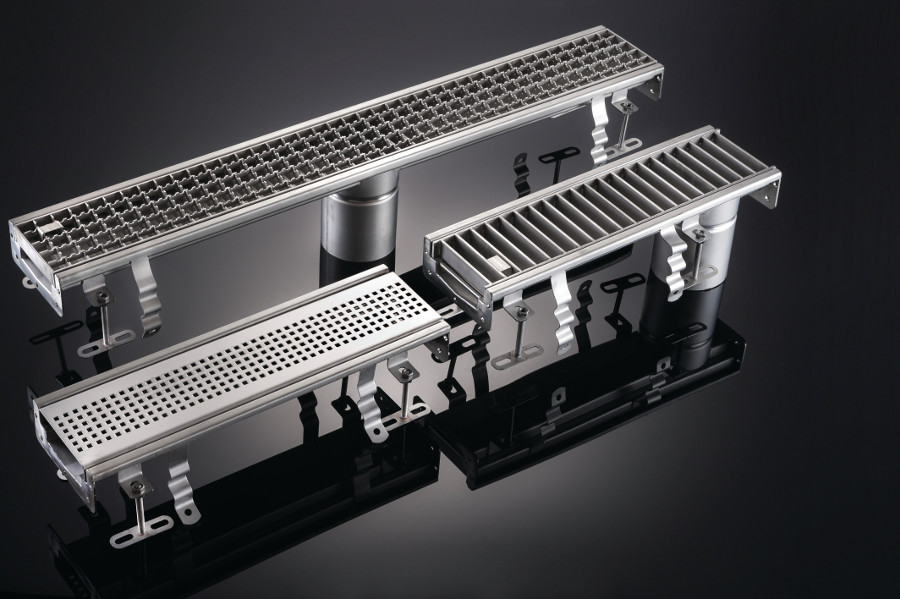

- All channel lengths are supplied with concrete anchor tangs and levelling

feet.

- Each channel section is jointed using bolted flange plates, with a

neoprene gasket to ensure a water-tight seal.

- Channels are available with closing end plates.

Benefits of Modular 120 include:

- The Modular 120 is a stocked channel range which is available on

reduced lead times compared to alternative Stainless Steel channel

solutions.

- Channels are supplied as standard with a vertical, trapped Ø110mm

spigots suitable for direct outlet pipe coupling or socket connection.

Spigots are supplied with a sieve as standard.

- Channel outlets are available in the centre or end of the channel

length.

- The maximum flow-rate for the vertical outlet is 1.2 l/s (through the

trap) making it an ideal solution for all applications including general

wash-down and shower applications. The spigot outlet trap has a

water trap depth of 50mm, which meets the requirements of BS

EN:1253.

- Stainless Steel is the hygienic material of choice, known for its

excellent anti-corrosion properties in areas where hygiene matters.

- The channel range is available with a variety of grating styles to suit a

variety of applications and meet the requirements of BS EN:1433 up

to Load Class C250.

- Channels are supplied with concrete anchors, to assist with

robustness during installation.

- Levelling feet assist with setting out prior to backfilling of the

channel system to ensure the channel is installed level and in

accordance with our installation details.

- Each channel section is jointed using bolted flange plates, with a

neoprene gasket to ensure a water-tight seal.

- Channels are available with closing end plates to suit the entire

range.

- All channel lengths are supplied with a synthetic edge for increased

resistance to high loads.