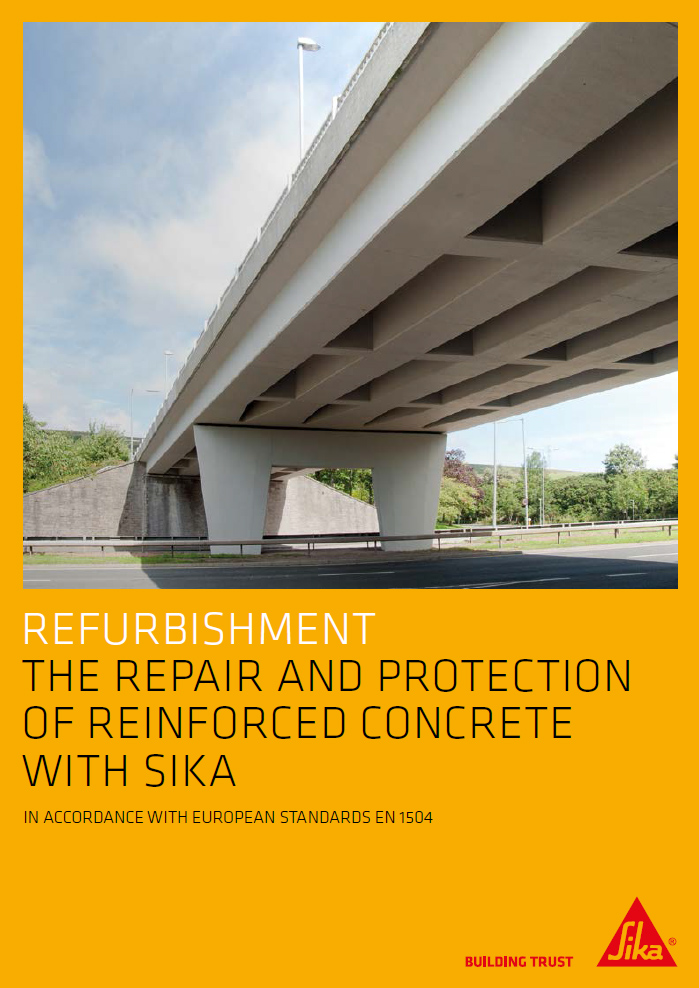

There is no defeating the ravages of time. Even at our most robust, our inevitable decline is merely being held at bay. Durable as it may seem, reinforced concrete is also susceptible to the passing years. Chloride and carbonation of its reinforcing steel can result in significant spalling in structures, particularly ones exposed long-term to sea salts or traffic pollution.

Patch repair, as the system suggests, is patchy at best. The long-term success of this course of action is severely hampered by the prevalence of chlorides in other areas of the concrete. Whilst removing and making-good the most-visibly spalled section of the structure might initially seem like a job well-done, the repair of only those sites which are actively corroding in a chloride-contaminated structure is likely to stimulate corrosion at sites adjacent to the repair. This phenomenon is known as the incipient anode, ring anode or halo effect.

Cause and effect

Consequently, patch repair proves far less cost-effective than addressing the source of the corrosion and carrying out a full concrete replacement. Now, here’s where the science kicks-in: whilst a concrete structure may be completely chloride-contaminated, leaving its reinforcing steel in a potentially corrosive environment, corrosion will only take place at specific locations due to steel corrosion being an electrochemical reaction in which there’s:

- An anode – the ‘actively’ rusting site where rust forms, eventually cracking and spalling the concrete

- A cathode – where the steel is protected cathodically and hydroxide ions are produced, further improving corrosion protection

- A flow of electrons along the rebar from the anode to the cathode, and a flow of hydroxide ions through the concrete from the cathode to the anode

Management benefits

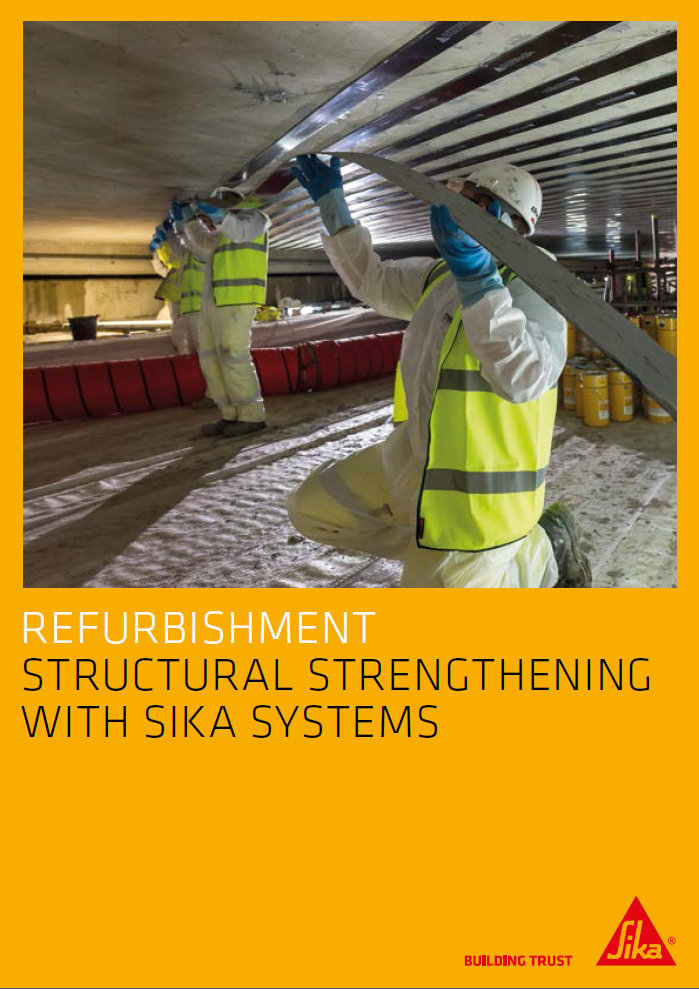

Corrosion management systems provide a cost-effective solution to reinforcement corrosion, helping reduce future maintenance costs and extend a structure’s lifespan. Used as part of a patch repair, targeted at specific high corrosion risk areas of structures, or installed over large areas for widespread corrosion protection and control. Instigating a total corrosion management programme, rather than implementing a simple patch repair, leads to a number of benefits.

These include:

- Long-term corrosion protection – minimising ongoing maintenance costs and extending the life of the structure

- No requirement for long-term connection of power supplies and control equipment – ensuring low running costs – may be an attractive option for remote structures

- May be targeted at specific areas or over an entire structure – ensuring cost effective protection

- Avoiding the need to break out large areas of contaminated concrete – reducing environmental disruption and avoiding the need for structural propping

Sika is the only construction manufacturer able to supply a comprehensive range of products for total corrosion management in the UK. Its Sika® Galvashield® range offers an example of how corrosion sites can be dealt with simply and effectively.

Its embedded galvanic anodes are used in concrete rehabilitation to prevent the formation of new corrosion sites adjacent to completed patch repairs and control corrosion in structurally sound chloride contaminated concrete

How does it work?

The anodes compromise a sacrificial zinc core that is activated by the surrounding specially-formulated cementitious mortar. The anode is quickly and easily fastened to the exposed reinforcing steel, and once installed, corrodes preferentially to the surrounding rebar. This protection technique is similarly used to protect steel on oil rigs and ship hulls.

The result of this ingeniously simple process is that the embedded anode provides galvanic corrosion prevention to the adjacent reinforcing steel and mitigating ‘Incipient Anode’ formation. As there is no need for an external power source, Sika’s galvanic systems are a popular choice for effective low maintenance corrosion mitigation.

With its superb Galvashield range, Sika has discovered a solution to the age-old issue of chloride-induced spalled concrete repair. It proves time need not be a barrier to a structure’s long-term health.