Easy and quick to install, Knauf Brio Dry Floor Screed is a superb substrate for perfect floors in new build and refurbishment projects that not only cuts construction times but also boosts both thermal and acoustic performance – and scores points on the sustainability front too.

Developed by Knauf Drywall – the UK’s leading manufacturer of lightweight building products and systems – Brio is an engineered gypsum flooring panel that has a very high thermal conductivity (R = 0.38 W/mK) so heating response times are quicker and energy use is reduced. When used in place of chipboard, Brio is proven to increase underfloor heating system efficiency by between 36% and 43%.

Once installed, Brio creates a robust monolithic floor with a high density of 1100 Kg/m3, and so cuts both impact and airborne sound transmission while its low profile minimizes the impact on floor-to-ceiling heights so it can easily meet Part-E of the Building Regulations.

Brio also helps buildings score well on BREEAM because of its high acoustic performance, low water content and because it facilitates the use of renewable energy sources such as ground and air source heat pumps by allowing underfloor heating systems to run cooler for the same output.

Brio’s largely recycled content of recovered gypsum and fibre, and its clean manufacturing process; means is it ideal for low-carbon buildings and reducing the carbon footprint in refurbishment projects. In use, Brio continues to reduce CO2 emissions throughout the life of the building.

Any competent tradesperson can install Brio Dry Floor Screed – no specialist trades are required because the boards are manufactured with precision, so that boards fit together smoothly and quickly. The result is that drying times on site are eliminated, as is the additional moisture in the building fabric that comes with wet screeds and there are none of the trip hazards associated with bulky batten and chipboard systems.

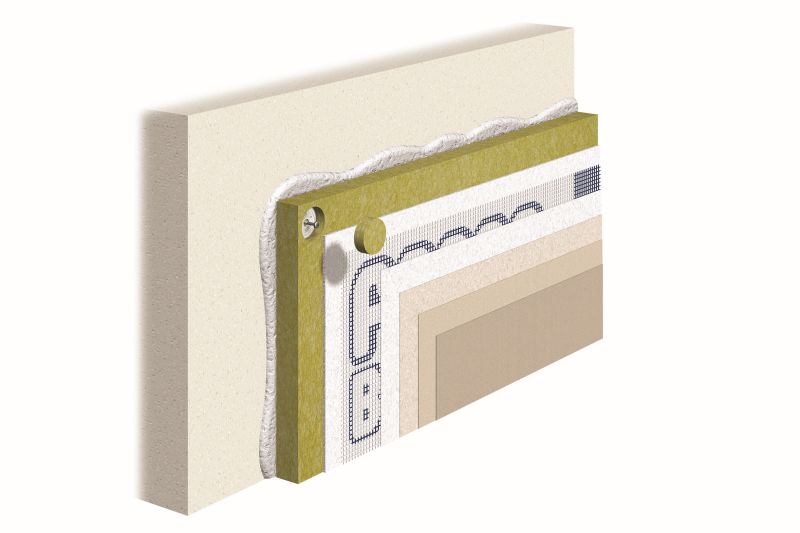

Panel joints are simply glued together and fastened with Knauf Brio Screws, designed to stop exactly 1mm short of the bottom of the precision-engineered panel, producing a solid, level floor that is ready for a wide variety of finishes – and traffic – within hours.

The panel is also ideal for refurbishments because of its low installation thickness of just 23mm, which allows for the installation of an underfloor heating system for a total loss in room height of just 50mm.

Knauf Brio is also much lighter than traditional wet screeds, significantly reducing loads and costly structural requirements in multi-storey buildings.

There are four Knauf Brio boards: Brio 18 (standard 18mm thick), Brio 23 (reinforced 23mm – recommended for underfloor heating applications), Brio 18WF and Brio 23WF.

The Brio WF (wood fibre) products are specifically developed as to be an effective floor treatment as part of an acoustic separating floor, and an instant upgrade in refurbishments. They are composite boards with an additional 10mm laminated wood fibre layer that provide high mechanical load resistance and effective footfall sound insulation and remove any need for acoustic battens.