Value engineering is a method to deliver essential project functions at the lowest cost. It substitutes materials and methods with cheaper alternatives without losing functionality. Focused on functions rather than physical attributes, value engineering is also known as value analysis.

Value engineering reviews products in the design phase to cut costs and boost functionality, enhancing product value. It aims to produce items cost-effectively without compromising their purpose. The concept of Value Engineering began at General Electric Co. during World War II. During the war, there were shortages of skilled labour, raw materials, and component parts. Lawrence Miles and Harry Erlicher at G.E. sought suitable substitutes.

Aligning Value Engineering with Structural Waterproofing

Messrs Miles Erlicher defined product value as the ratio of function to cost. Function is the work an item is designed to perform, and cost covers its life cycle expenses. Increasing product value involves enhancing function or reducing cost. Value engineering includes analysing costs related to production, design, maintenance, and replacement.

Product value = Function

Cost

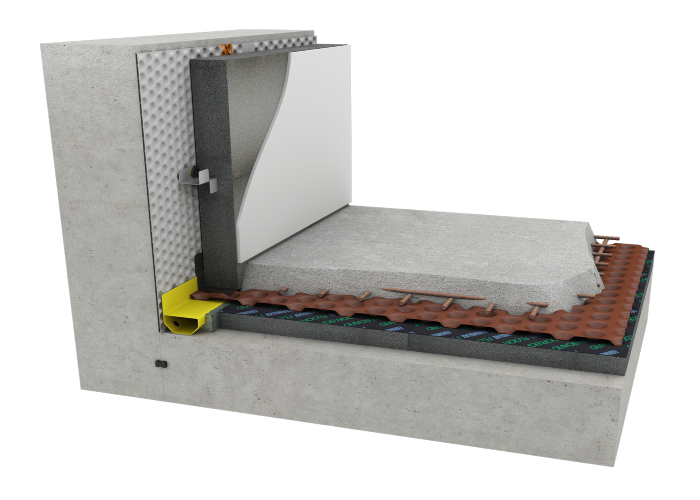

Waterproofing requires a tailored design approach, as there is no one-size-fits-all solution.So, to achieve value engineering in structural waterproofing, consideration should be given to product, Product performance characteristics, installation, future maintenance and worst-case scenario, refitting flawed or failed systems.

Waterproofing is vital for maintaining the integrity and value of a structure. Poor workmanship, wrong materials, lack of preparation, or missed details during installation can cause failed waterproofing systems, leading to water damage and expensive repairs.Addressing waterproofing issues early ensures a structure stays in great condition. Although waterproofing costs only 2-5% of a building's total expense, to rectify failed or flawed waterproofing, can account to nearly 80% of all construction-related problems.

Effective structural waterproofing relies on precise product selection and proper installation methods from the start.

Waterproofing Design

Waterproofing design is essential in construction, employing various methods and materials to prevent water ingress. Effective waterproofing design enhances building longevity and safeguards structures against water damage.

Three key stages to successful waterproofing: design, specification, and installation.

The waterproofing designer will assess “value” and incorporate this into their design.Not all waterproofing products/materials are equal. Different products offer varied qualities and features, so it's important to choose the right one for the project.

A Waterproofing Design Specialist must know various waterproofing systems and BS 8102:2022. They should understand water sources, their interaction with structures, and soil flow. Structural principles and geotechnical knowledge are essential for working with engineers and interpreting soil reports.

Delta Technical Team

Delta's Technical Team can help you find value engineering solutions for your waterproofing project. For all your project requirements, Delta's Technical Team is a dependable resource. Offering expert advice, comprehensive support, and timely practical assistance, we cater to your specific needs. Contact us today to optimise your project's performance and cost efficiency.Tel: 01992 523 523 or drop us an email at info@deltamembranes.com.