Design professionals in the construction sector deal with a complex and often conflicting array of challenges in a cost-conscious industry. As well as a raft of standards and regulations, style and function often seem to be competing demands in the search for a solution. So how can manufacturers help designers strike a more even balance? Housing Specification magazine looks for answers.

An adage drilled into many first-year design students says: “Good architecture should satisfy in commodity, firmness and delight”

It’s a popular saying penned by seventeenth century translator, Henry Wooton, but attributed to Vitruvius Pollio, a Roman Architect of the 1st Century BCE. As sayings go it’s a good one, but what does it actually mean and how can manufacturers help designers strike a more even balance?

The accepted view is that commodity referred to fitness for function – the item, be it a building, a piece of sculpture or a manufactured product - should be suitable for its purpose.

In firmness, Pollio meant it should soundly built of good quality materials. And for delight, he meant pleasing to the trained as well as the untrained eye.

So, in satisfying these demanding criteria, the building or item in question must look good, perform well and be durable. It has to successfully balance style and function.

Of course, there are many other factors architects and designers need to consider in modern construction. Factors such as low environmental impact, minimal waste, maximum use of recycled materials and innovative use of new technology.

These challenges are very real and the supply-side of the industry has consistently raised its game in the search for new products and solutions.

In the manufacture of roofline and rainwater systems, the need to accommodate style, function, environmental awareness and use of modern technology, have all contributed to the development of a highly flexible, cost efficient and durable range of products that perfectly tick the respective boxes of commodity, firmness and delight.

For example, timber used to be the material of choice for roofline work – fascias, soffits, barge boards and the like. But in such a challenging environment, a softwood fascia board is unlikely to survive more than a couple of decades, especially if it doesn’t receive regular maintenance including re-painting at least once every three years or so.

CELLULAR PVC – THE MATERIAL OF TODAY.

As a result, cellular PVC is now the most efficient material for use at the roofline. It costs roughly the same as timber to install, requires no maintenance and so suits the exposed and inaccessible location at the eaves. Most importantly, especially from any landlord’s point of view, when it is installed correctly, it will probably last the lifetime of the dwelling.

As well as these functional attributes, cellular PVC also keep an aesthetic card up its sleeve. Cellular PVC is an extruded, foamed material with an integral smooth and durable skin. A wide range of colours and foil finishes [skins] are available, providing a considerable degree of flexibility in co-ordinating and contrasting with popular window and door styles, as well as coloured rainwater management systems.

Cellular PVC can be cut, drilled, nailed and routed using conventional tools. It is light to handle, easy to fix and does not require any painting or subsequent treatment after installation.

STYLE AND FUNCTION

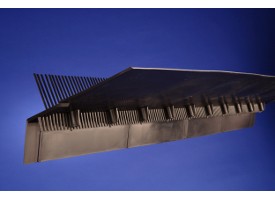

Decorative profiles can also be factory-made which allow designers to match traditional, vernacular detail. A good example is a roofline detail found in rural Wales where award winning developers, PAR Homes used sculptured boards from Swish Building Products to enhance 45 homes at their Bronllys site in the Brecon Beacons. [Pictured]

At their Court Meadow site, PAR Homes created a “village” environment within Bronllys town and the Swish profiled barge boards help visually connect the new development with the heart of the existing community.

According to, Swish, cellular PVC also represent an environmentally responsible use of plastics. Not only do they not contain CFCs, lead or cadmium, which are considered harmful to the environment, but the Company’s manufacturing processes have also taken huge strides over the last decade by reducing its production CO2 footprint by a third since 2008 and its use of water by nearly 80% in the same period. Swish also points out that cellular PVC has a very long-life span and when replaced, can be fully recycled.

COMPLEMENTARY RAINWATER SYSTEMS

Swish also manufactures a complementary range of rainwater management systems – guttering, fall pipes and attendant bracketry – all designed to efficiently collect and dispose of rainwater run-off from building roofs.

For designers looking to replicate the traditional cast iron guttering profiles, Swish manufactures an authentic reproduction of original designs, accurately made in all the traditional profiles, sections and sizes and with a surface texture that makes them highly appealing and cost-effective alternatives to the hugely more expensive, real thing.

A FINAL THOUGHT.

Few designers today enjoy the luxury of unlimited budget and a totally free creative hand. This is not necessarily a bad thing, nor should it prevent a stylish and functional solution to a challenging design brief. What we should strive for is good design, well executed with the right materials, that will stand the test of time.

And within budget. As Pollio said many years ago: “Commodity, firmness and delight”.

For more information on Swish rainwater systems and cellular PVC roof line products, contact:

Swish Building Products:

01827 317 200

www.swishbp.co.uk