Panel Systems, one of the UK’s leading distributors of Styrofoam, is supplying the University of Sheffield with Styrofoam sheets that are being used in ground breaking research projects.

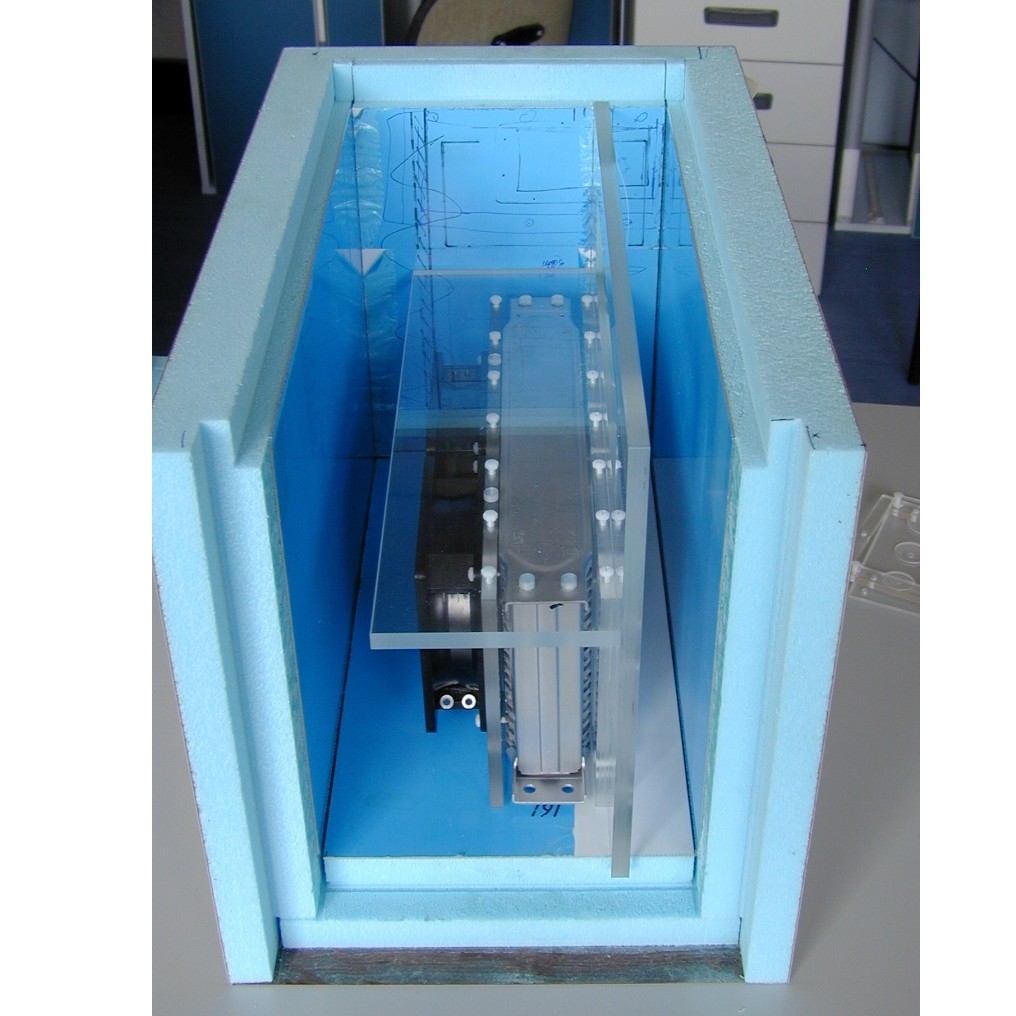

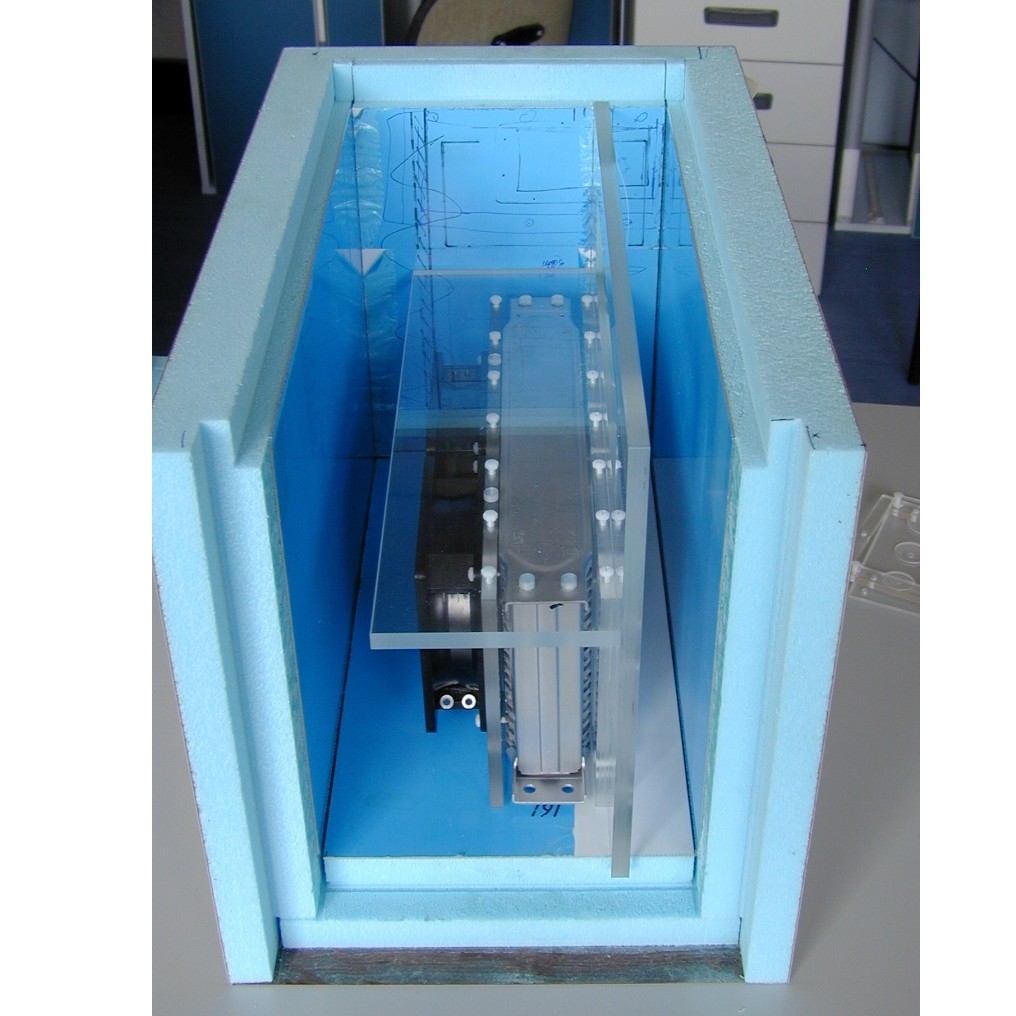

The extruded polystyrene sheet material is widely used for the construction of thermal chambers for irradiation facilities and silicon detector thermal testing here in the UK, as well as at CERN, the Central European Nuclear Research Agency in Geneva. Styrofoam is used in the active beam line of CERN’s Large Hadron Collider.

The LHC is the world’s largest machine, lying 100 metres underground, beneath the border between France and Switzerland. It aims to allow giant detectors, such as the ATLAS & CMS experiments to reveal the secrets of the universe, by examining the world’s tiniest particles. The LCH hurls particles at a velocity approaching the speed of light, which then collide with each other and the detectors record the resulting events caused by the collision.

Dr Richard French of the University of Sheffield said: “We have used Styrofoam in our experimental applications such as acoustic shielding and thermal chambers for 15 years and have found it to be reliable, clean and safe. It means we can achieve the results we are looking for quickly and effectively. There are many properties of the material which lend itself well to use in our ground breaking research programmes.”

Danny Phelan, Sales Manager at Panel Systems, said: “It is fascinating to be able to supply our Styrofoam sheets for projects that are enabling scientists to better understand the universe. Styrofoam is renowned for its high performance, so it is little wonder it has been specified for this high profile LHC project.”

Styrofoam is one of the world’s leading brands of extruded polystyrene. It is renowned for its exceptional thermal performance, high compressive strength, and low water absorption, making it the preferred choice for a wide range of industrial, academic and construction applications.

Styrofoam is available in a number of different grades and sheet sizes to suit the end use. Panel Systems can supply Styrofoam hot-wire cut to any thickness from 3mm to 165mm at tolerances as low as +/- as +/- 0.20mm. The company offers a full 5-Axis CNC machining service, and can accept customers own drawings in a variety of formats.

Panel Systems has over 40 years’ experience in supplying Styrofoam and has two extensive production and warehouse facilities close to the M1 in South Yorkshire where customers can collect Styrofoam products, or they can be delivered direct to site.