Structural engineers and fabricators will be able to enjoy significant system weight savings thanks to the launch of a new purlin and side rail system, with improved supporting software.

Developed by the Hadley Group in response to customer demand, the new UltraZED2 delivers on average weight savings of between six and 13 per cent compared to other market leading systems.

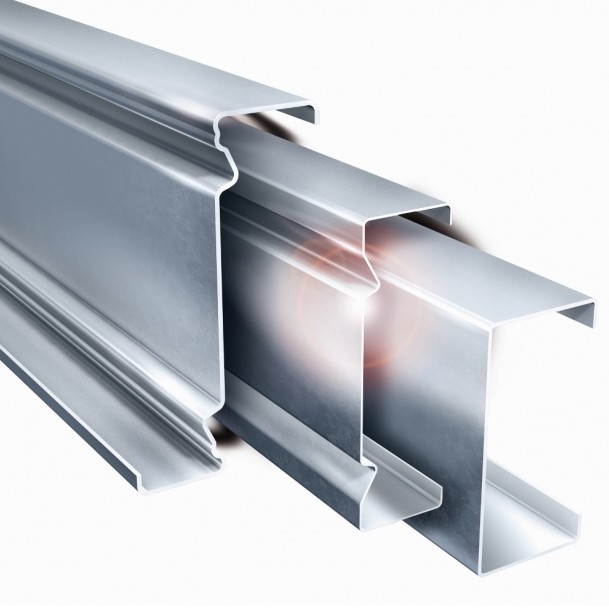

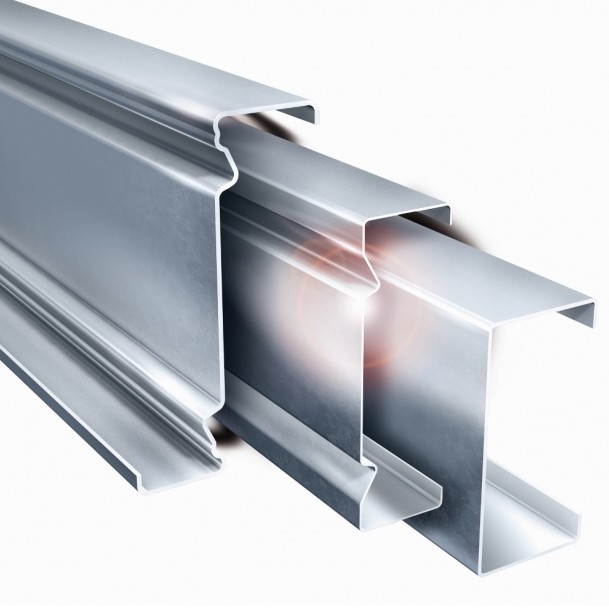

The UltraZED2 purlins, UltraBEAM2 side rails and all components in the range have been completely redesigned and tested extensively. The result is a new purlin profile that is both lighter and stronger than competitor systems. It has a generous 70mm flat fixing face, enhancing both sheeting installation and air permeability performance.

Available in both single and double span systems, the section range has been expanded to fill design criteria cases where solutions were not available. There are now 59 UltraZED2 sections manufactured from high strength S450 steel. These range from a section depth of 145mm to 305mm enabling engineers to design for spans up to 13 metres. The products offer considerable improvements to the load capacities across the full range of systems which include sleeveless double span, sleeved and Heavy End Bay systems.

Hadley’s advanced Design SuitePRO software has also been completely redesigned to support the new purlin range, making choosing the right gauge and depth option for the job both quick and easy. With contemporary user interfaces the software is designed to be completely intuitive and can be used with the minimum of training.

It features SCI Assessed section properties and system capabilities considered in accordance with Eurocode BS EN 1993 1-3, (current BS version incorporated). The integral module utilises BreVe.3 for calculating wind loadings and features an extended range of Internal Pressure coefficients as well as a bi-directional wind wizard. The wizard assesses wind speed from 12 directions in just six steps, and allows for custom labelling of each face of the building under consideration for quick and easy identification of correct loads. All elements of the building can be incorporated in a stored project database, which can be configured to the user’s output and reporting requirements in Microsoft Word or .pdf formats.

Speaking about the launch of the new UltraZED2 purlins system, Brian Cartwright, Product Development Manager of Hadley Group said: “Since we launched the original UltraZED back in 1985, technology has changed, design and build processes have changed and regulations have changed, which of course means that the needs of structural engineers and fabricators have changed. With this in mind, rather than simply evolving the existing system, we have gone back to the drawing board and engineered the new UltraZED2 purlin and side rail systems from the ground up.

“We firmly believe that the resulting system is ‘loads better’! It features a new purlin profile helping to ensure the whole system is both lighter and stronger, which in real world applications will deliver significant cost savings, both in terms of material costs and man hours, as well as enhanced environmental benefits.”

The Hadley Group was founded more than 50 years ago and is the UK’s largest independent producer of cold roll-formed sections and winner of the Queens Award for Enterprise Innovation 2014.

It is the largest British owned producer of cold rolled sections and allied products employing over 500 people with an annual turnover over £100 million sterling (US$ 195 million). As a supplier to numerous industries including automotive, construction, agriculture and aerospace the company rolls more than 125,000 tonnes of steel annually. Business is carried out with 36 countries covering five continents.