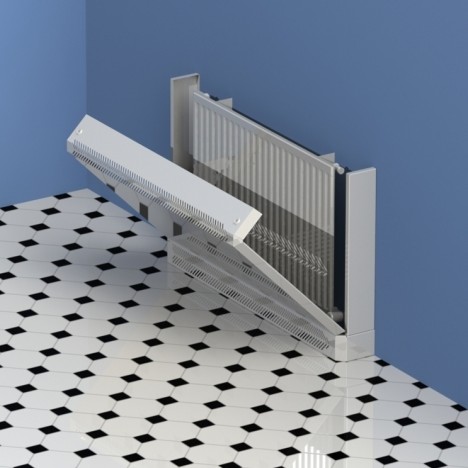

Clarke Delta Ltd are delighted to announce the arrival of their new full access LST Radiator Guard, designed to provide protection to service users, against burns and injuries from falls against hot radiator surfaces. The innovative design has been developed after years of working alongside Industry professionals to overcome common challenges in their environments.

Public Health England have also recognised the importance of ensuring infection control in buildings by releasing a set of guidelines. A recent study highlighted a reduction in bacteria on radiators of over 90% by using an LST Radiator Guard that has an anti-bacterial coating.

Maintenance and facilities staff have the challenge of maintaining the comfort of service users by ensuring the operation of heating facilities, radiator valves which control the level of heat are at risk of been damaged or tampered with whilst exposed. The Clarke Delta full access LST Radiator Guard protects radiator valves, whilst also allowing authorised people complete access.

The sharp edges on radiators or valves provide another area where protection is required to ensure the safety of service user, guards with chamfered sides help protect service users against the impact of falls against sharp edges. Our efficient grill design also prevents fingers, and consumables such as pencils being pushed into the radiator guard.

Fixed radiators guards with no access, can restrict the heat output from radiators due to a build-up of foreign objects including dust and dirt. When fixed radiator guards are installed, it requires maintenance or facilities staff to remove the guard, and domestic staff to ensure the surface is hygienic. A potential cost saving is provided by having a guard with a simple full access opening, which can easily be completed by domestic staff.

At Clarke Delta Ltd we offer free site consultations to ensure our products provide the perfect solution to our customer’s challenges.

Reasons to choose us:

-

Engineered Designed Products – Our products are always designed with our customer’s in-mind.

-

Bespoke Manufacture – All our products are manufactured bespoke to give our customers the best solution to their problems.

-

ISO9001 Manufacturer – Quality is a key ingredient to ensure success, that’s why we manufacture our products using proven and reliable techniques.

-

Efficient Installation – Products are individually detailed, considering the installation process.

-

Offsite Detailing – Where possible cut-outs are completed in manufacture, giving a factory finish.

-

Robust Materials – Quality materials and designs are utilised to ensure a long life expectancy, which our customers deserve.

-

Environmentally Friendly – Mild steel used to manufacture our products has a high intrinsic value supported by a well-developed and efficient scrap collection system.

-

Technical Support – We enjoy engaging with our customers, as it helps provide the best service and solutions. So send us email or give us a call.