Marshalls, the UK’s leading hard landscaping manufacturer, has announced the findings of a major project undertaken in collaboration with world renowned engineer Professor John Knapton, to review their market leading Priora permeable paving system.

Marshalls Priora is a SUDs solution which keeps paved areas clear of standing water without the need for complicated and expensive drainage systems – all the while providing an attractive, hard wearing surface suitable for any loading requirement. In addition, the Priora system cleanses water that flows through the structure and returns it straight back to the water table at source.

After 10 years of in situ experience with a zero failure rate, Marshalls embarked on a major study to ensure that the design advice offered was still up to date and relevant for modern applications. It employed a combination of laboratory test results, finite element analysis and Professor Knapton’s worldwide experience to arrive at a series of results. The findings have lead to a new series of design models which ensure best possible practice, reduce costs, provide environmental benefits, and truly reflect the requirements of today’s customers.

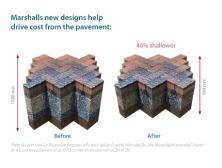

Marshalls’ new series of 9 sub base design models now provide more flexibility to clients than the 6 offered by the British Standard; the new models have been developed to reflect modern requirements, allowing a closer link between the required application and the level of recommended design. From light to heavily trafficked applications, and now including a heavy duty ports and docks option for static loads, the new models offer a more flexible approach than ever before. The Marshalls expert design team can now be even more prescriptive in their advice, and in the majority of cases, help to drive cost from the pavement structure.

Research was also carried out into the patented design of the Priora nib; 6 nibs per block each feature 8 separate faces which interlock in 3 different directions. This unique combination maximises rotational interlock between blocks – a feature which has been proven to reduce pressure on the sub base. Priora is the only permeable paving block on the market to demonstrate full rotational interlock through full scale testing, therefore providing clients with the confidence that they have a permeable paving system which will perform.

This rotational interlock enhances surface stiffness. Crucially, understanding this feature has allowed Marshalls to review and enhance the design of the sub base below a Priora pavement. The majority of new revised designs, which cater for all ground conditions, require shallower depths than Marshalls previous recommendations, therefore reducing costs and minimising time on site. By reducing the required amount of imported aggregate and, in excavation jobs, waste off site, the new options also offer enhanced environmental benefits – while still providing the required levels of hydraulic performance.

Chris Griffiths, Marshalls Water Management expert, said: “We worked with Professor Knapton on our initial Priora system design 10 years ago. Our own understanding of the technology has increased enormously since then, and this, combined with Professor Knapton’s worldwide experience, has given us a solid foundation from which to investigate new design methods.

“Marshalls Priora is the market leading permeable solution in the UK; in fact, since its launch Marshalls has sold enough Priora to pave nearly 500 football pitches, and enough water flows through these installations to fill over 1,100 Olympic sized swimming pools every year. However, we don’t believe in resting on our laurels and so we’re always seeking ways to improve our products and their performance.

“As the pending national SUDs standards seem to be preoccupied with the cost of installing a sustainable drainage system, it’s great that these new design models make a Marshalls Priora installation more cost effective than ever before.”

Professor Knapton said: “It’s been really interesting investigating why Marshalls Priora has performed so well over the past 10 years. Once we understood the rotational interlock advantage provided by the unique nib, it gave us the confidence to revise my initial design models which Marshalls have been using. The result is a new series of dependable, value-engineered models which truly reflect modern usage.”

For more information on Marshalls Priora, the product review, or issues surrounding water management, please visit www.marshalls.co.uk/wm or call Chris Griffiths on 01422 312083.