The ability to match a bespoke existing design and work to a tight deadline were the twin challenges facing London marble and terrazzo specialist Diespeker in an iconic Soho restaurant.

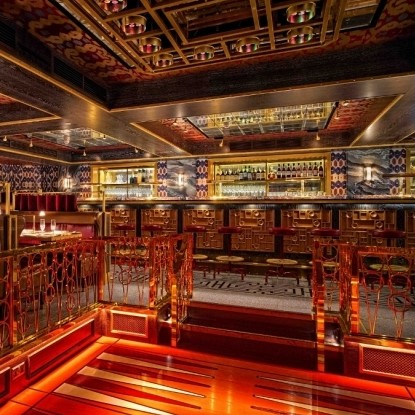

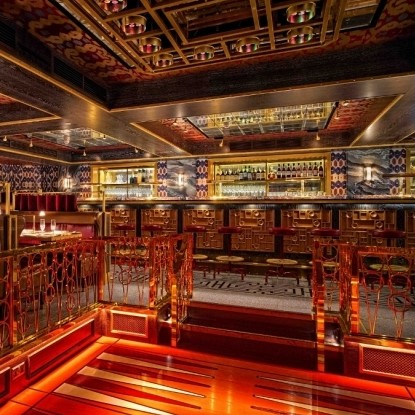

Described as dripping in the glamour of the Gatsby era Bob Bob Ricard has been the place for the wealthy to partake of perfect cocktails and lobster mac with cheese since it opened five years’ ago.

Earlier in 2014, Bob Bob Ricard underwent a £3 million investment to extend the flamboyant eatery by creating a Club Room in the basement.

To create a sense of continuity, owner Leonid Shutov was keen for the existing ground floor design by David Collins (of The Ivy and The Wolseley fame) to be reproduced in the revamped downstairs dining area.

Stone flooring specialist Diespeker initially supplied and installed conglomerate marble for the restrooms at an early stage of the fit out. This required Diespeker to match the existing design of the restrooms on the ground floor which had a black, gold and beige finish. 80m² of tiles were required for flooring, cladding and urinal fins.

Contractor WCF contacted Diespeker later in the year to discuss the next challenge; the recreation of the flooring in the restaurant itself. The first challenge was to match the bespoke terrazzo, including a unique inlaid design spelling out the words ‘Bob Bob Ricard’ in a darker hue.

On top of this was the deadline of five weeks from commission to completion, with a week to source the materials and four weeks on site. Within this timescale, Diespeker had to create the inlay, ship in purpose-made terrazzo and lay 120m² of flooring. The restaurant is an iconic and exclusive establishment, so there could be no compromise on quality.

Diespeker called on its preferred supplier in Verona to make the bespoke terrazzo in sheet format. Although Diespeker makes and cuts terrazzo at its factory in Bermondsey, the finished material for the Bob Bob Ricard floor needed to be thinner than usual.

“Our Italian supplier uses a mechanised process that adds density to the concrete by compression and vibration,” explained Diespeker MD, John Krause. “This means that the blocks of terrazzo can be sliced into finer sheets.”

The specific marble for the terrazzo chips came from the Greek island of Thassos. Thassos marble is a snow white marble that gives a purer finish to other white marbles such as Carrara.

When the terrazzo arrived at the UK factory, a number of sheets were allocated to the CNC cutting machine for the inlaid sections. These were cut initially to be oversize, then polished. Black terrazzo was laid by hand into the grooves produced the CNC machine by experienced craftsman, Andy Brady, and the panels ground and re-polished before being cut once again to provide a perfect fit.

The remaining sheets were cut into 600 tiles of 600x600mm. The intricate inlaid pattern flooring was laid out on the factory premises to check the pick up and alignment of each panel before being taken to site for installation.

For the main restaurant flooring, Diespeker’s expert fixing team were under major pressure, particularly as the other trades were working at the same time in order to complete the fit out on time. “It was a crucial factor for Diespeker to co-ordinate with the contractor, WFC’s programme. The team worked out of hours to ensure the install went smoothly and to programme,” said John.

Reviews speak of the finished Club Room as ‘meticulously executed and faithful to the original David Collins design.”