A truly innovative approach to structural glazing installation has enabled industry-leading commercial glazing specialists GLASSOLUTIONS to overcome a series of stringent health and safety limitations on a high-profile commercial project in central London.

Using a specially designed sliding track system, GLASSOLUTIONS was able to reduce the glass installation footprint for the site, safeguard the installation team from the risks associated with working at height, and advance the speed of the installation at One Bedford Avenue by a very considerable margin.

Occupying a prominent corner of Tottenham Court Road, One Bedford Avenue is a multi-use development which combines commercial offices with retail units to create a versatile multi-use space. Designed by Stirling-nominated architects Bennett’s Associates, One Bedford Avenue replaces two outdated office blocks with highly attractive and energy efficient spaces, with natural light on three sides and spectacular views at the upper levels.

Working with project managers Mace, GLASSOLUTIONS delivered a semi-bespoke window system, with window profiles designed specifically for the project to meet the design intent and to accommodate associated building movements.

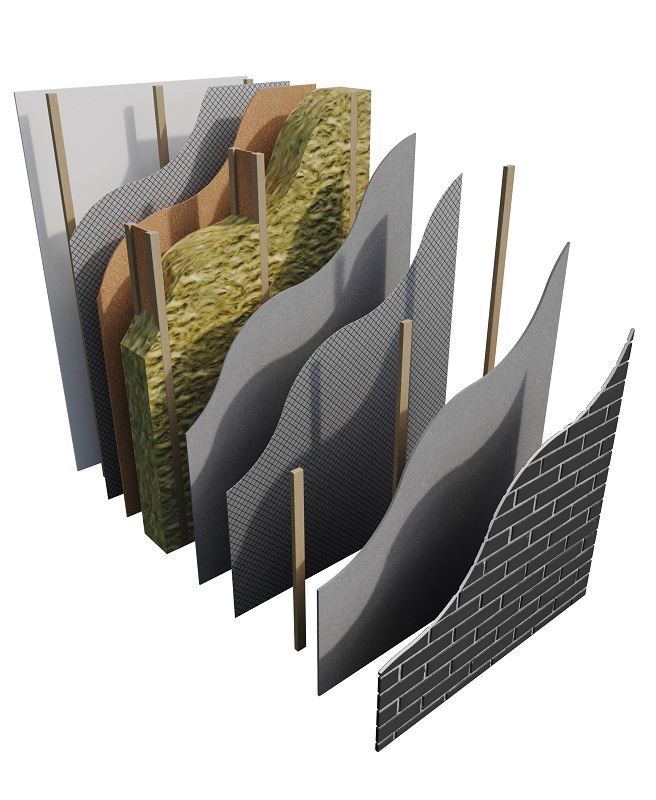

Wicona curtain walling provided aesthetic benefits as well as well as superior U-values and air tightness ratings; GLASSOLUTIONS’ unique VS-1 structural glazing system also formed an integral part of the installation, with the building’s main entrance and reception area using the system to achieve an attractive aesthetic effect.

However, the tight specification was not the only issue the GLASSOLUTIONS Installation team had to resolve. With extremely limited external access and a site perimeter not much greater than the building’s footprint, a high priority for the project was to create a safe method of working that could be completed from the inside of the building.

Additionally, with other building work taking place concurrently, it was essential that as much as possible of the floor slab area could remain operational and safe throughout the installation process.

To meet these challenges, the GLASSOLUTIONS project team created an innovative sliding track system to move the glass units across the floor plate, and place them on to the façade at the place of installation. As well as removing the need for floor cranes, this installation method allowed the installation team to remain safely behind perimeter protection at all points in the process whilst also freeing up the floor slab for other trades to operate safely.

In addition to safeguarding the onsite team from many of the risks associated with working at height, GLASSOLUTIONS’ unusual installation system delivered further benefits for the project.

As well as reducing the number of operatives required to move each unit, the new process allowed units to be fitted at a greatly improved rate, increasing from an anticipated 4.5 units per day per team (using a traditional floor mounted crane) to an impressive peak of 17 units. These combined benefits allowed the installation to achieve an accelerated programme, to the client’s great delight.

GLASSOLUTIONS’ work at One Bedford Avenue took place over June and July 2016, and the full construction project was completed in March 2017. On GLASSOLUTIONS’ involvement, Clive Everett, GLASSOLUTIONS’ Design and Technical Director, said: “One Bedford Avenue was a development which presented us with a complex set of constraining parameters, requiring the design team to respond with an innovative and bespoke solution.

"A clear understanding of the client’s needs, combined with good communication and a collaborative attitude were key to ensuring that the installation was successful.

“In the end, not only was the installation itself a triumph, but our innovation-led approach to ticking all the project’s boxes had other positive results, such as increasing our rate of installation and enhancing safety. This sets a new precedent for the GLASSOLUTIONS contracting division – going forward, we hope to be able to apply the processes we used on the One Bedford Avenue project to deliver similar benefits to future installations.”