Housebuilders are taking greater control of their supply chains as supply of materials gets stretched.

This has led to a significant increase in the offsite and modular construction market, particularly in the housebuilding industry as developers seek to achieve Government targets for both private and social housing.

Manchester-based housebuilder Urban Splash has bought the loss-making Building Systems business from materials group SIG. Persimmon, which already has its own timber frame operation, Space 4, and a manufacturing plant in Harworth with capacity to produce 80 million bricks a year, will now start manufacturing other materials.

A 25,000 sq m factory in Harrogate has been built by Ilke Homes, which is a joint venture between housebuilder Keepmoat and offsite specialist Elliott Group. Legal & General opened a 550,000 sq ft factory in Selby last year to manufacture offsite housing in Selby, while Ashley House took majority control of F1 Modular, the offsite business that is the only modular contractor to hold a place on the local government LHC National Framework NH1.

The Lloyds Bank annual housebuilding report revealed that 68% of housebuilders are investing in modular housing and 56% are putting cash into panelised systems of construction. According to the Lloyds’ report, average investment in new building techniques by housebuilders now comprises 24% of turnover compared to 20% five years ago.

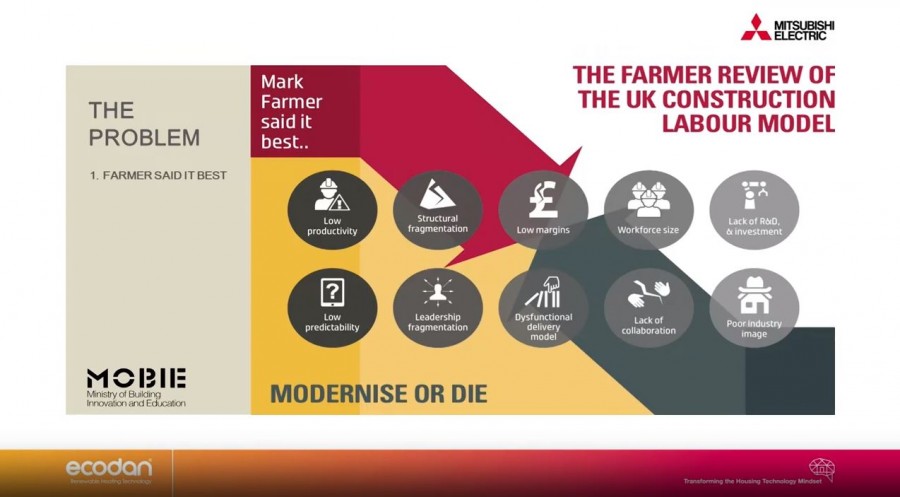

Glenigan’s economics director Allan Wilen commented: “These changes are because housebuilders are concerned about their margins.

“Skills shortages are endemic and the threat of tariffs when the UK leaves the European Union both loom large and bigger housebuilders are likely to explore similar deals going forwards.”

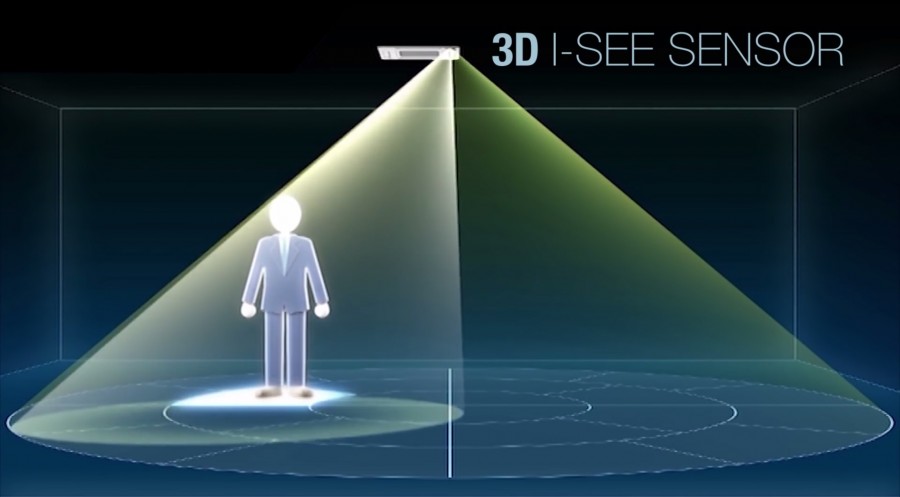

The long-term sustainability benefits of offsite and modular construction often mean that when specifying products and systems, the design team will look at the most energy efficient solutions available. This helps in terms of marketing offsite construction properties as more environmentally friendly.

Indeed, many offsite and modular projects now feature the use of key sustainable products and systems - green roofs, ground and air source heat pumps, solar panels, solar shading and rainwater harvesting – in their own marketing literature

In turn this enables manufacturers such as Mitsubishi Electric to position both their domestic and commercial heating ranges as ideal systems for offsite and modular projects.

Several trends have been driving the market for panelised modular building systems. The drive towards sustainable development, coupled with the need to meet energy efficiency and carbon reduction targets, would seem to weigh in favour of offsite construction.

Panelised modular buildings also generate less waste, typically have superior airtightness, and hence thermal insulation performance, than brick and block construction.Key end use sectors for panelised modular building systems are private and social housing, apartment blocks, schools, hotels, healthcare and care facilities and purpose-built student accommodation.

Residential applications account for around 65–75% of the overall market, reflecting the predominance of timber frame in the building of both private and social housing.

“Over the next few years to 2022, there are several factors that will underpin a steady growth in this sector, probably over and above that forecast across the overall construction industry," said Keith Taylor, Director of AMA Research.

"These include an increasing use of Building Information Modelling, and an increasing number of public sector procurement frameworks.

“More importantly there is now a strong likelihood of an increase in the use of volumetric and other types of offsite construction method to help meet the chronic housing shortage and cope with the lack of traditional construction skills within the construction industry.”

(This article first appeared on The Hub, Mitsubishi Electric's information resource)