Faced with ever-tightening building regulations, the balcony-to-slab junction has become a focal point for architects, engineers, and specifiers seeking to balance structural integrity, thermal efficiency, and fire safety. In higher-risk buildings (HRBs), this scrutiny has intensified by the Building Safety Act and the ‘Golden Thread’ of information which require that every element contributing to occupant safety is fully documented, robust, and compliant.

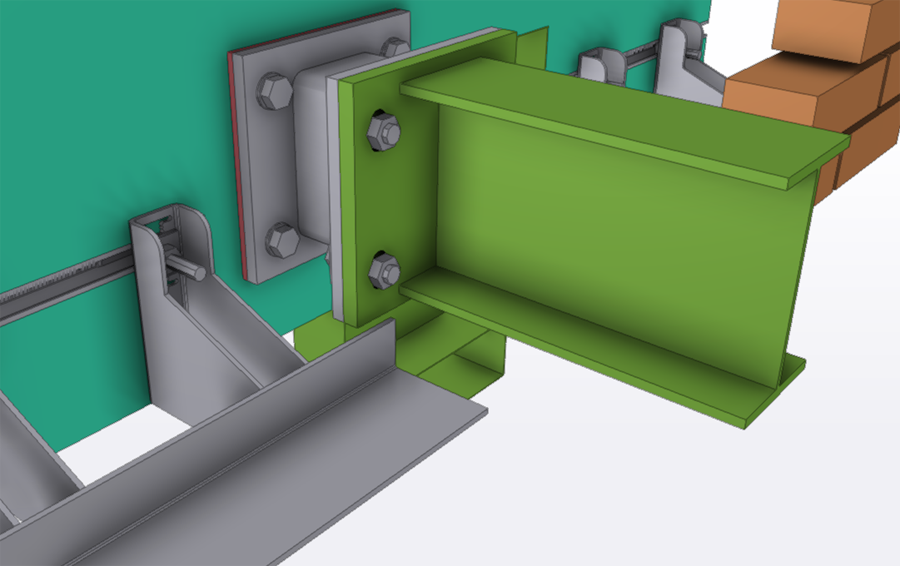

Balcony connectors were once a largely functional detail but are now under closer regulatory focus for their performance in three critical areas: thermal bridging, fire resistance, and structural stability. Historically, thermal breaks were introduced to alleviate thermal bridging and the subsequent problems of mould growth in habitable areas, whilst more recently thermal breaks were increasing employed to limit heat loss. Early designs often used polystyrene or other combustible materials, raising concerns for fire safety and compliance.

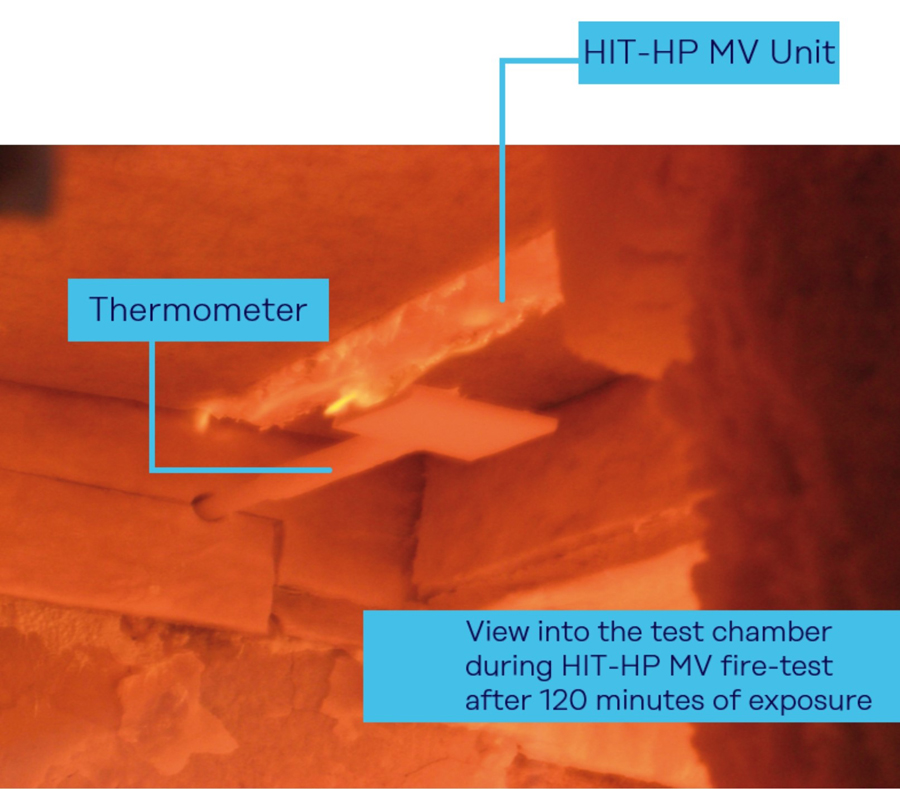

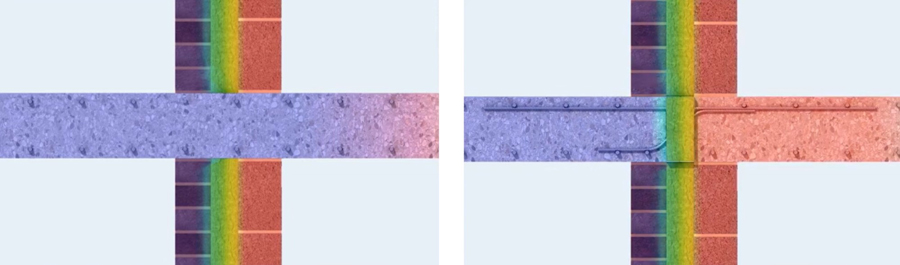

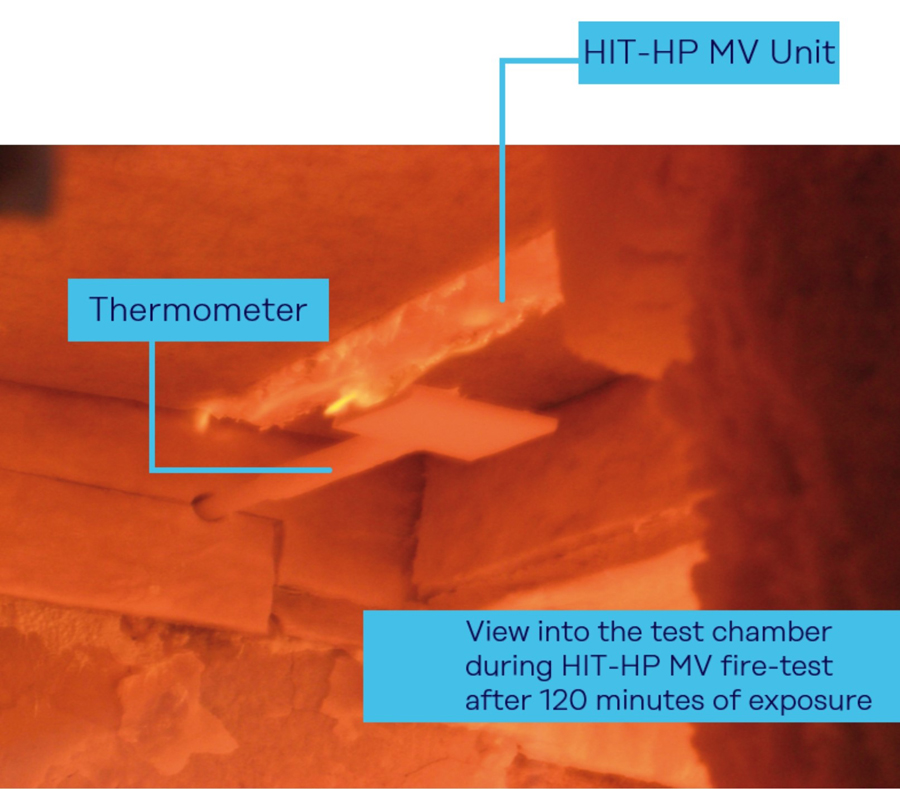

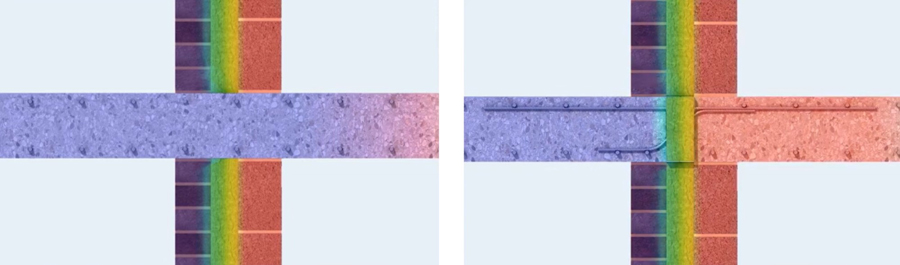

Today, effective fire resistance is a vital consideration. In buildings over 11 metres, it is preferred that balcony connectors with thermal breaks are made from A1 or A2-s1,d0 non-combustible materials and supported by integrated fire barriers to achieve performance classifications such as REI 120, which covers load-bearing capacity (R), integrity (E) and insulation (I) for 120 minutes. This protects the structural system by limiting heat transfer and supports compartmentalisation strategies.

To mitigate thermal bridging, high performance mineral wool insulation (typically 80–120 mm thick depending on the project) combined with robust water-resistant membranes, provide an effective barrier while maintaining thermal performance.

Complex loads

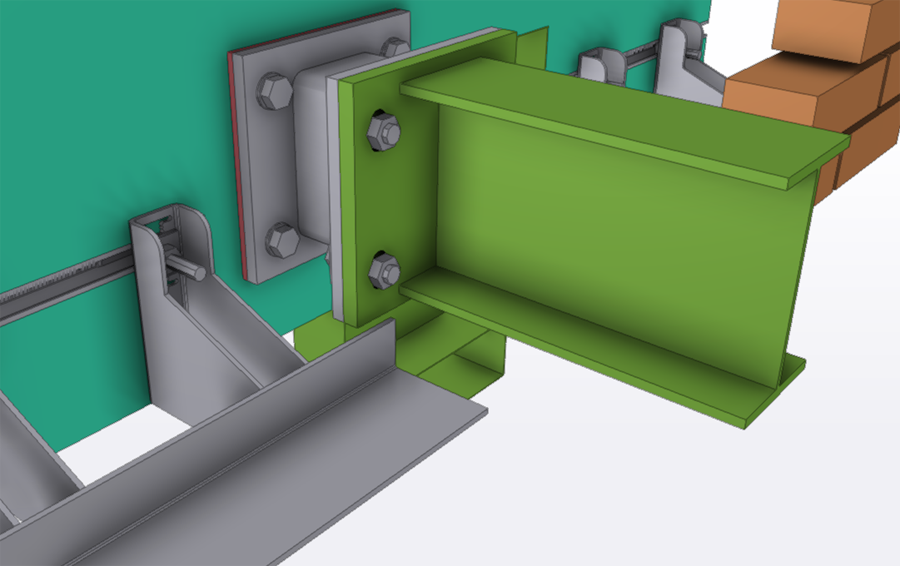

The specification challenge is compounded by the complex loads and geometry of modern balconies, particularly in curved or irregular designs. Steel reinforcement within thermal break and Ultra High-Performance Concrete (UHPC) compression shear bearings must withstand compression and tying forces without compromising structural performance. Engineers must carefully consider rebar diameters and module design to ensure the balcony remains secure, particularly under unexpected loads or site conditions. When these elements are incorrectly specified or installed, this can compromise thermal performance, which can lead to condensation and ultimately undermine the building envelope’s thermal function.

Early collaboration

Early engagement between manufacturers and project teams is increasingly recognised as essential. Collaborating at the design stage allows for optimisation of thermal break specification, evaluation of movement joints, and resolution of potential conflicts with other structural or masonry elements. This collaboration also ensures that Passive House/Passivhaus or high-performance projects can meet stringent energy requirements while avoiding costly redesigns or site interventions.

Digital technologies are playing a pivotal role in this process. Building Information Modelling (BIM) enables early clash detection, precise positioning of connectors, and integration of thermal and structural analyses. Finite Element Analysis (FEA) and cloud-based design tools are being developed to accommodate more complex balcony geometries, allowing engineers to visualise performance under load and to assess fire and thermal compliance before construction begins.

Ultimately, achieving safe, compliant and structurally robust balconies depends on early collaboration and informed specification.By taking a proactive approach with thermal break manufacturers such as Leviat will mean that structural, thermal and fire performance requirements are integrated seamlessly rather than addressed in isolation. It also supports compliance with the Building Safety Act and the gateway process. At a time when the construction industry continues to prioritise greater accountability and transparency, recognising balcony connectors as critical components rather than hidden details will be key to delivering safer and more resilient buildings.

Learn how to specify balcony connectors for safe, efficient, and durable designs in the Leviat CPD training - The Importance of Correctly Specified Thermal Breaks and the Considerations around Slab Edge Complexity.

To find out more about specifying high-performance balcony connectors, including Leviat’s Halfen HIT and Ancon STC (Steel-to-Concrete) and STS (Steel-to-Steel) insulated connectors, visit Leviat.com, email info.uk@leviat.com or call 0114 275 5224.