Traditional brickwork has long been a popular façade finish, offering rich textures and durability. However, with increasing demands for efficient construction— alongside the growing trend to use brick on mid- and high-rise buildings— brick slip systems have emerged as a modern, lightweight and versatile alternative to full-depth bricks. While they offer design and installation advantages, they can also introduce fire safety challenges.

Passive fire protection considerations for brick slip systems

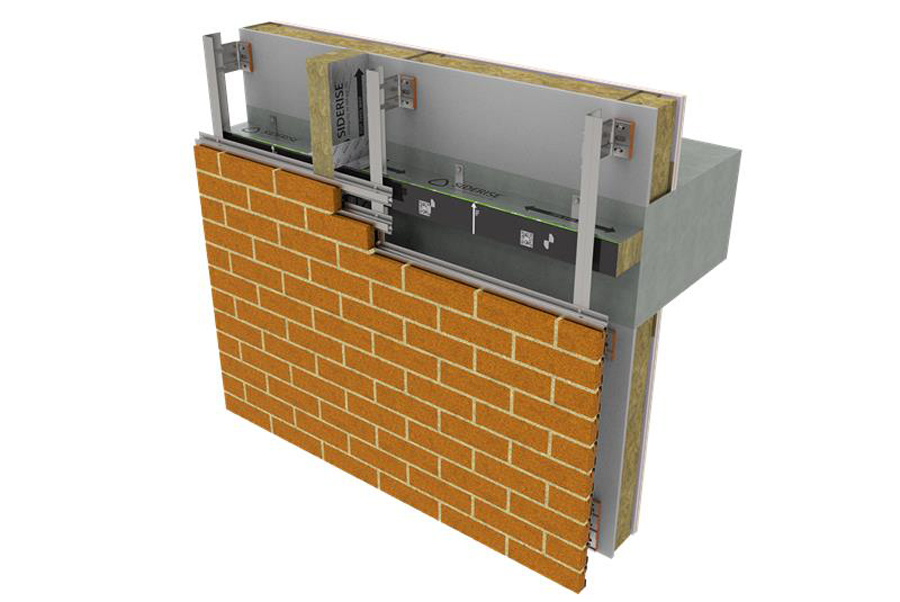

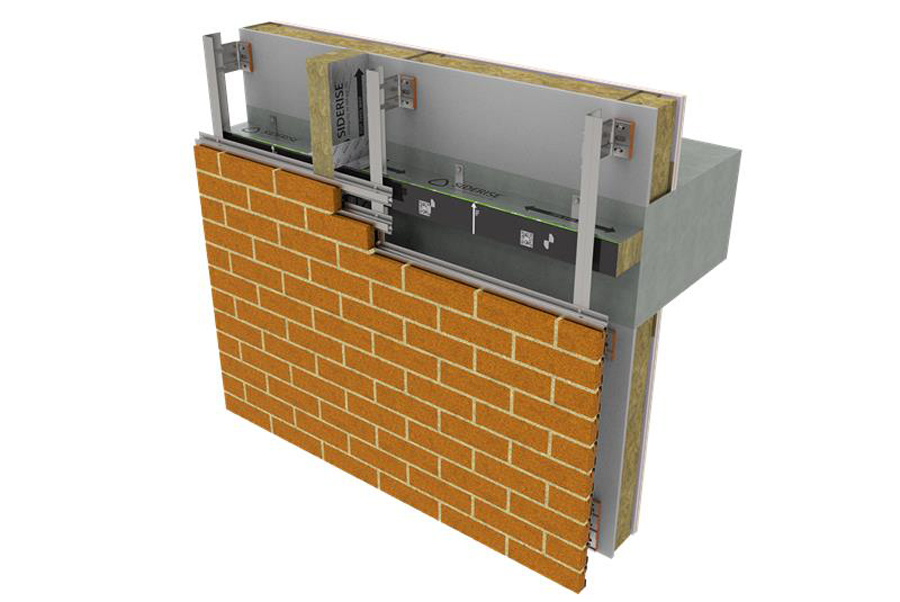

Of the various brick slip cladding systems and configurations on the market, ventilated mechanically fixed systems are a common choice in the UK. These typically comprise slim brick ‘tiles’, which are mechanically secured onto a supporting metal carrier rail as part of a rainscreen faҫade construction. These emulate traditional, full-scale brickwork while supporting cost-, time-, and space-efficient construction methods.

Whilst many brick slip faҫades have non-combustible components, the fire resistance of the complete assembly requires careful consideration to ensure regulatory compliance and reliable performance. Not only does this include addressing the open cavity between the inner construction and outer finish by closing it off with effective compartmentation, but assessing the individual requirements of different systems.

The problem with standard cavity barriers

Rainscreen façade constructions are designed to allow any moisture that penetrates the external facade to drain through the gap between the exterior and the insulation layer. It is important that the cavity barriers installed allow for this daily air/water flow, whilst still effectively sealing the cavity in the event of a fire entering the system.

However, brick slip systems can differ widely in design, currently making it difficult for a standardised approach to compartmentation. For example, some systems use a ‘clip in’ rail fix and others a ‘dovetail’ fix, which present interfacing complexities. There is also the added challenge of the irregular cavity sizes within the void created by the profile of the brick tiles and the rail system. The cross section of the tile can include a profile or ‘frog’, these small, indented areas between each tile are difficult to effectively seal with conventional vertical and horizontal cavity barriers, additionally there can be hidden voids behind carrier rails. In the past, the solution has been to extensively notch and scribe full fill cavity fire barriers onsite to match the system’s inner profile. However, this approach is time-consuming, inconsistent, and often lacks supporting fire test evidence.

Bespoke-for-brick-slip cavity barrier solutions

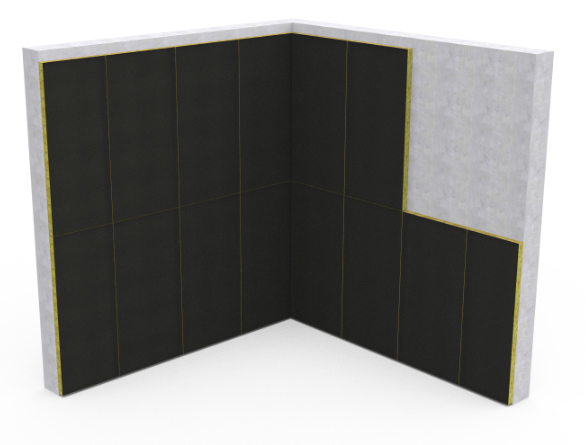

Horizontal partial fill ‘open state’ cavity barriers (OSCBs) are commonly used for vertical compartmentation in rainscreen façade systems. Fixed to the inner construction, the integral intumescent strip on the barrier’s leading edge activates at a critical temperature (typically around 130°C) and exfoliates to meet and mould to the face of the external leaf. These are combined with vertical full fill cavity fire barriers to prevent lateral fire spread.

Of course, not all OSCBs are suitable for all systems, and it is vital to ensure that the chosen solutions have been appropriately designed, developed and independently tested for use with the intended system, and that the test configuration matches the project’s design. This provides assurance that the OSCBs will achieve a robust seal between the inner construction and outer brick slip, with no small gaps left for the flames and smoke to migrate through. To address the current issue regarding a non-standardised approach to brick slip passive fire protection design, some passive fire manufacturers with UKAS accredited in-house test facilities can re-engineer existing rainscreen cavity barriers to develop effective bespoke barrier solutions.

Passive fire protection solutions developed for brick slip facades can also carry benefits during the construction stage. For example, projects teams have found that vertical cavity barriers with a lamella core can be installed under increased compression. This means that there is no need to install intermittent intumescent strips running vertically between each rail. This not only reduces material costs but also speeds up installation—enhancing the efficiency benefits of brick slip systems.

Beautifully safe

Brick slips offer huge potential to bring the beauty of bricks to all types of buildings. However, it is important to specify these systems alongside fully tested and third-party certified passive fire protection, designed for use in that specific application.

Learn more about passive fire protection for rainscreen systems at siderise.com