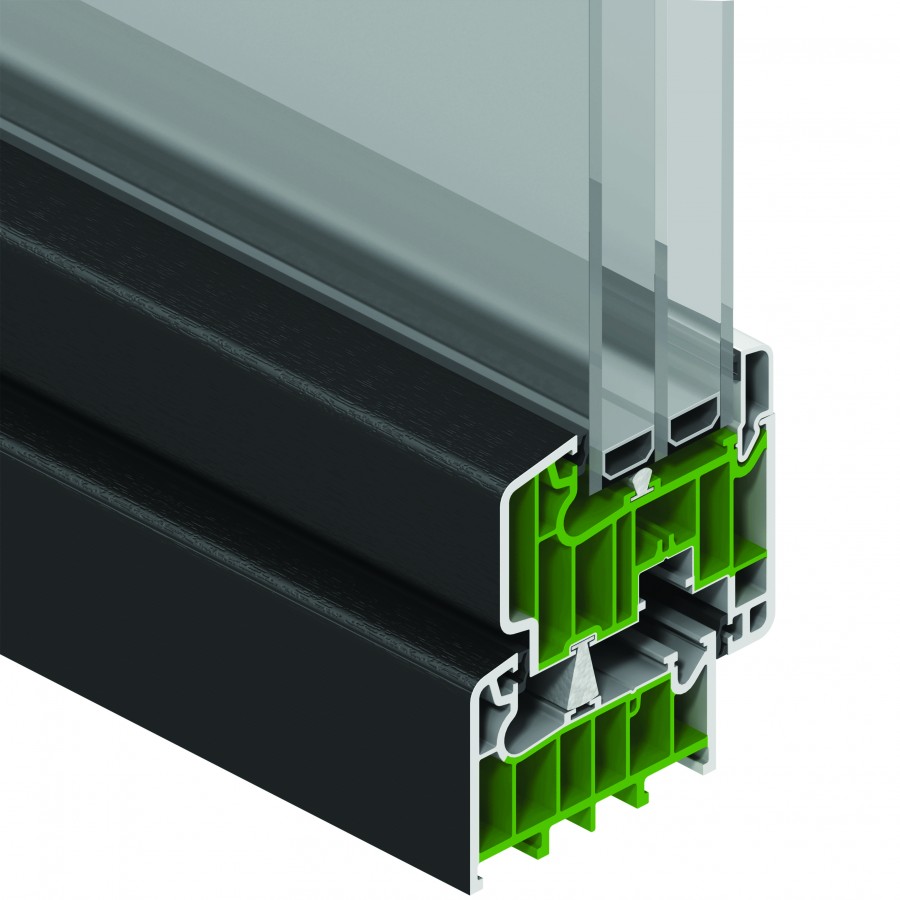

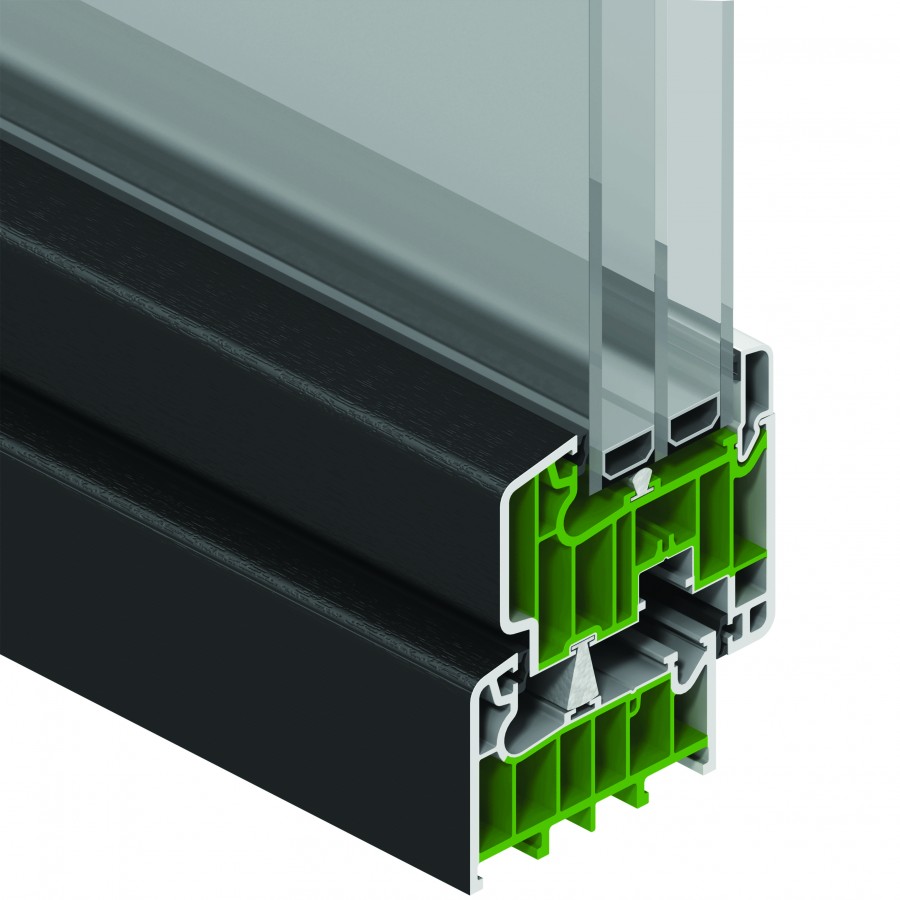

Set against other product choices such as aluminium or timber composite, PVC-U offers long-term durability and high performance, attractive aesthetics, and cost-effective value. In addition, thanks to Eurocell’s recycling processes, it presents a sustainable product solution that positively supports the specification market.

Eurocell has been committed to the sustainability benefits of recycling for over two decades.During this time, the company has evolved a market leading recycling service that enables it to meet two primary objectives: it helps prevent clients having to send end of life plastic window and door frame waste to landfill and, secondly, it enables Eurocell to recycle old plastic waste into new PVC-U extrusions, which in turn are used to produce new attractive and sustainable window and door solutions.

With increasing scrutiny on the origins of product manufacture as part of specifications, Eurocell’s two waste plastic recycling plants sit at the heart of the Eurocell-Recycle service and their combined effort is delivering real benefit.

Using a ‘closed loop’ recycling system that deals with both post-consumer and post-industrial plastic window waste, the plants are responsible for processing over 40,000 tonnes of plastic window and door frame waste per year.

The closed loop system is a six-stage recycling process.Old and discarded plastic windows, door frames and other plastic offcuts are collected by Eurocell’s fleet from company sites and waste management centres across the UK.On arrival, the material is sorted and separated to divide metals, white polymer, and coloured materials, as well as capturing material which is non-recyclable.

After a transformative process which creates a powder or pellet form, the recycled plastic is used together with virgin PVC-U material by Eurocell to manufacture its extensive range of extruded plastic products.

In addition to an ongoing commitment to a large-scale recycling strategy, Eurocell’s positive contribution to the availability of greener product solutions for specifiers is found within the PVC-U material itself.

With the objective of assessing the sustainability credentials of recycled PVC-U as a responsible product material solution, the Faculty of Science and Engineering at Manchester Metropolitan University recently reviewed an array of data sets and modelling emanating from peer-reviewed publications. This was undertaken to create an accurate life cycle assessment of the use of recycled PVC-U window frames within Eurocell’s manufacturing operations.

The subsequent academic findings provide further compelling evidence that the specification of recycled Eurocell window and cavity closures is advantageous when it comes to making a sustainable product choice.

As an example, the research discovered that a typical semi-detached house comprising seven windows and a pair of French doors will see an average weight of post-consumer

PVC-U within the eight products plus cavity closure of 122kg.As a result, a development constructing on average 2500 units of semi-detached houses will save around 627 tonnes of CO2 equivalent per year by specifying recycled Eurocell windows and cavity closures versus an alternative solution that specifies full virgin PVC-U windows.

As we approach the introduction of changes to Part L of the Building Regulations and plan for the impact of the Future Homes Standard - which is seeking a 75% reduction in CO2 in new buildings by the middle of the decade - specifiers responsible for selecting building fabric products can choose recycled PVC-U solutions from Eurocell to support a more sustainable, energy efficient, and less wasteful future.

For more information about Eurocell’s range of PVC-U solutions and its commitment to a sustainable future, please visit: https://www.eurocell.co.uk/eurocell-recycle