By Angus Mackie - President QUALICOAT UK & Ireland

There has been a great deal of discussion that has taken place of late over the combustibility of the external envelope of some of our high-rise dwellings where aluminium composite panels (ACM) containing flammable cores have been used. These panels are in the process of being removed and replaced to meet stringent new standards. Insurance companies, mortgage providers and other property stakeholders have also had their part to play to mitigate risk and have forced building owners to check for ACM and other issues such as areas of timber decking. All this will ensure a safer building stock for our city’s high-rise dwellings.

Above Image: Anodised Aluminium Sheet - tested to BS 8414

Above Image: Pre-Coat Aluminium Sheet - tested to BS 8414

Above Image: PPC Aluminium Sheet - tested to BS 8414

The surface spread of flame on a high-rise dwelling can cause fire to spread quickly from floor to floor and legislation is now in place to ensure construction designs slow down the spread of a fire through the building envelope, or to stop it altogether, by correctly specifying the materials used in the building project. As a result, new and refurbished buildings deemed to be high-rise, over 18m in England (11m in Scotland), will be considerably safer.

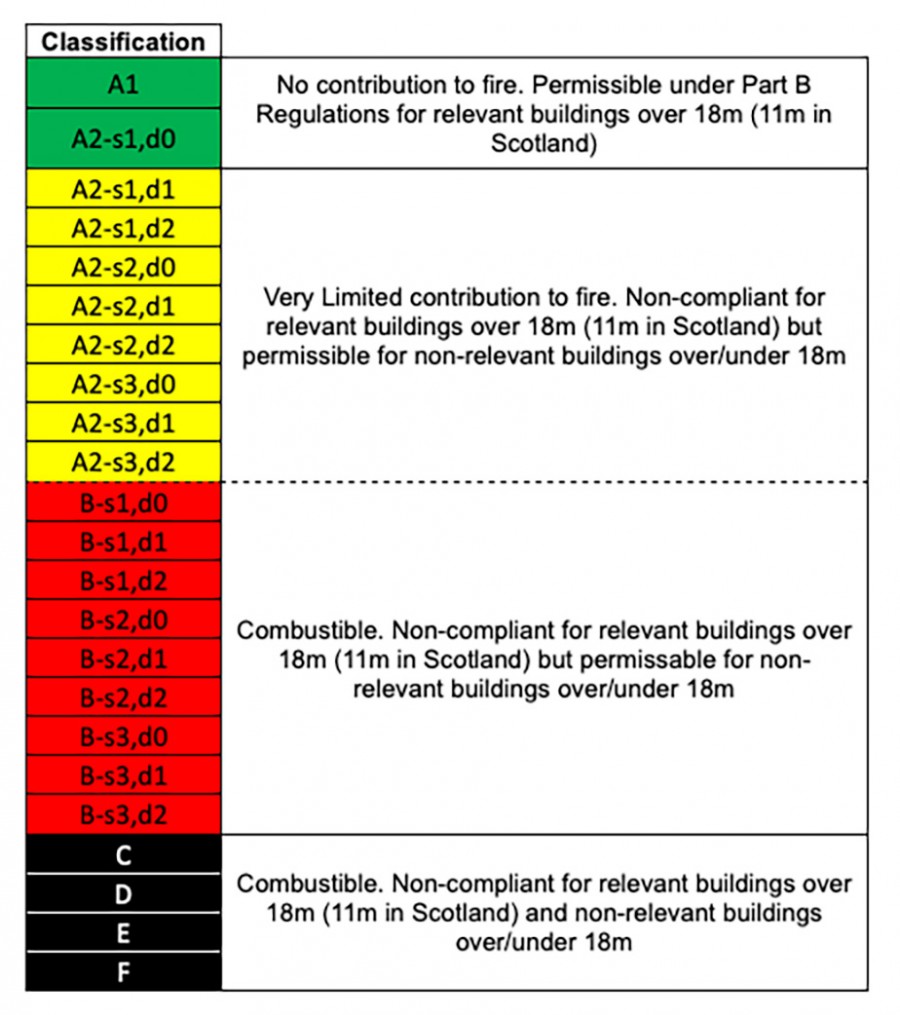

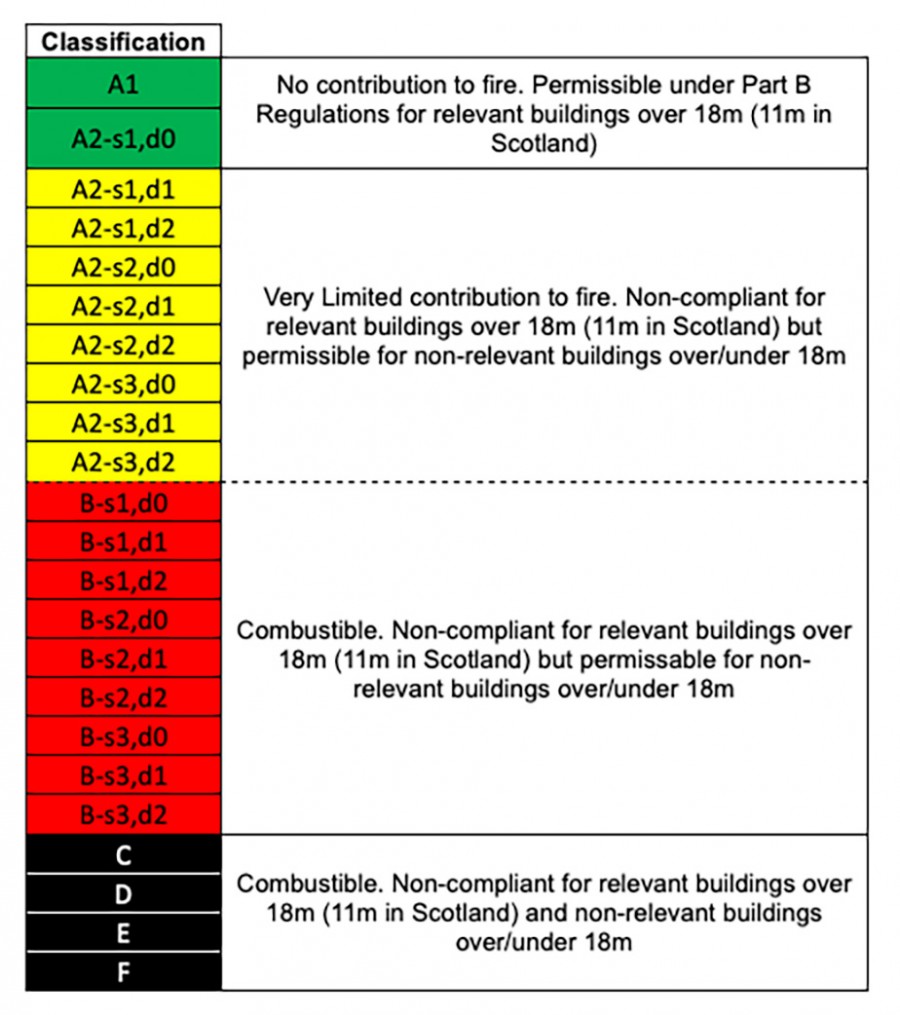

Of late members of QUALICOAT UK & Ireland have seen a rising number of powder coating specifications that request an ‘A1’ classification for combustibility under BS EN 13501-1. When traced back through to the specifier, the origin of this requirement largely stems from property stakeholders who are misguidedly attempting to mitigate their risk by exceeding the current guidance, standards and legislation currently available. This can add both complexity and costs to projects without any benefit or reduction of risk.

When applied at standard industry thicknesses, architectural Polyester Powder Coating (PPC) achieves an ‘A2-s1,d0’ classification. This classification is required for compliance to the amended Building Regulations 2010 (Approved Doc B: Fire Safety) Nov 2018 and accepted as providing the necessary protection from the surface spread of flame on high-rise construction and other legislated buildings.

Ultimately, PPC does not promote combustibility or fire spread when tested to BS EN 13501-1. This is further supported by the testing required for London Underground approval, often lauded as a barometer of fire safety. This requires compliance to EN 45545, where spread of flame is measured objectively (ISO 5658-2) unlike BS EN 13501-1 which involves visual assessment only. Furthermore, PPC smoke production is extremely low or non-existent (s1) with no flaming droplets (d0). On the chart of combustibility, ‘A2-s1,d0’ sits just under the ‘A1’ classification.

It is important to assess the cladding system holistically and not just the performance of the constituent parts under BS EN 13501-1.

Above Image: The fire classes stipulated in BS EN 13501

The predominant fire test for the whole external cladding system is BS 8414. This provides a route to compliance for buildings over 18m that are outside the scope of Part B regulations. This requires materials to meet the performance criteria given in BRE report BR 135 which measures whether the cladding build up is deemed safe for buildings at elevated height. The test itself involves a 9m high wall with a complete cladding installation, including the fixing of panels and insulation. It is therefore a through-the-wall test.

When tested to these stringent fire safety standards, PPC performs as well as anodised and pre-coated aluminium sheet material. The three images for each of the tests show the cladding after the test, then with cladding removed and then with insulation removed to show the membrane.

A blanket specification of ‘A1’ restricts the choices of colour for the facade, also it will no doubt incur increased supply costs and shows a lack understanding of the standards and current best practice. But, irrespective of whether aluminium cladding is ‘A1’ or ‘A2- s1,d0’ classified, the critical aspect is to ensure the full system is specified, configured and installed correctly. This ultimately governs all safe cladding installations.

In closing, QUALICOAT UK & Ireland firmly believe that the ‘perceived’ reduction in risk is not necessarily mitigated by moving from ‘A2-s1,d0’ classification to ‘A1’.

Members of QUALICOAT UK & Ireland believe education on the subject is required and will be approaching the relevant property stakeholders, such as insurance companies, local councils, developers and building funders. QUALICOAT UK & Ireland will make representation to protect the industry, to ensure specification freedom and to negate unnecessary surface finish costs.

A more detailed guidance note is available on the QUALICOAT UK & Ireland website.

The next QUALICOAT UK & Ireland members meeting takes place on 19th October 2021, at the Arden Hotel & Leisure Club, Solihull , please contact the General Secretary, Jan Lukaszewski, via the QUALICOAT UK & Ireland website, should you wish to attend. For details on the availability of various colours and finishes contact any QUALICOAT UK & Ireland member for more information. For updated information about the use and specification of QUALICOAT in the UK and Ireland, please visit the UK & Ireland Association website at www.qualicoatuki.org