The 2018 Building (Amendment) Regulations and two subsequent government advice notes regarding combustible materials on building exteriors have given rise to wave of refurbishment projects, as local authorities and private building owners respond to pressures to follow safety guidelines. It has prompted a surge of demand for replacement materials and systems that enable fast installation with minimal disruption to building occupants.

The 2018 legislation prohibits combustible materials on newly-built residential buildings with floors above 18m, but the government advice notes of 2019 and 2020 recommend the immediate removal of such materials from all existing buildings, regardless of floor height. This advice has widespread implications for multi-storey apartment buildings, especially in relation to the often complex process of replacing potentially unsafe balconies.

Removing and replacing balcony materials such as decking and balustrade can be extremely disruptive to existing residents. Noise, dust and light pollution from construction work can have a widespread effect on those around it. In some cases, access to homes could be blocked, requiring temporary accommodation which not only involves major inconvenience for residents, but also significant cost to local authorities and building owners.

These factors make modular building systems – pre-engineered off-site for faster and easier installation – an ideal solution for balcony refurbishment. Modular products are manufactured in multiple components that are then combined on site to form the complete system; this means that the time on site is vastly reduced. With no hot works required for assembly, they also greatly reduce noise, dust and light pollution.

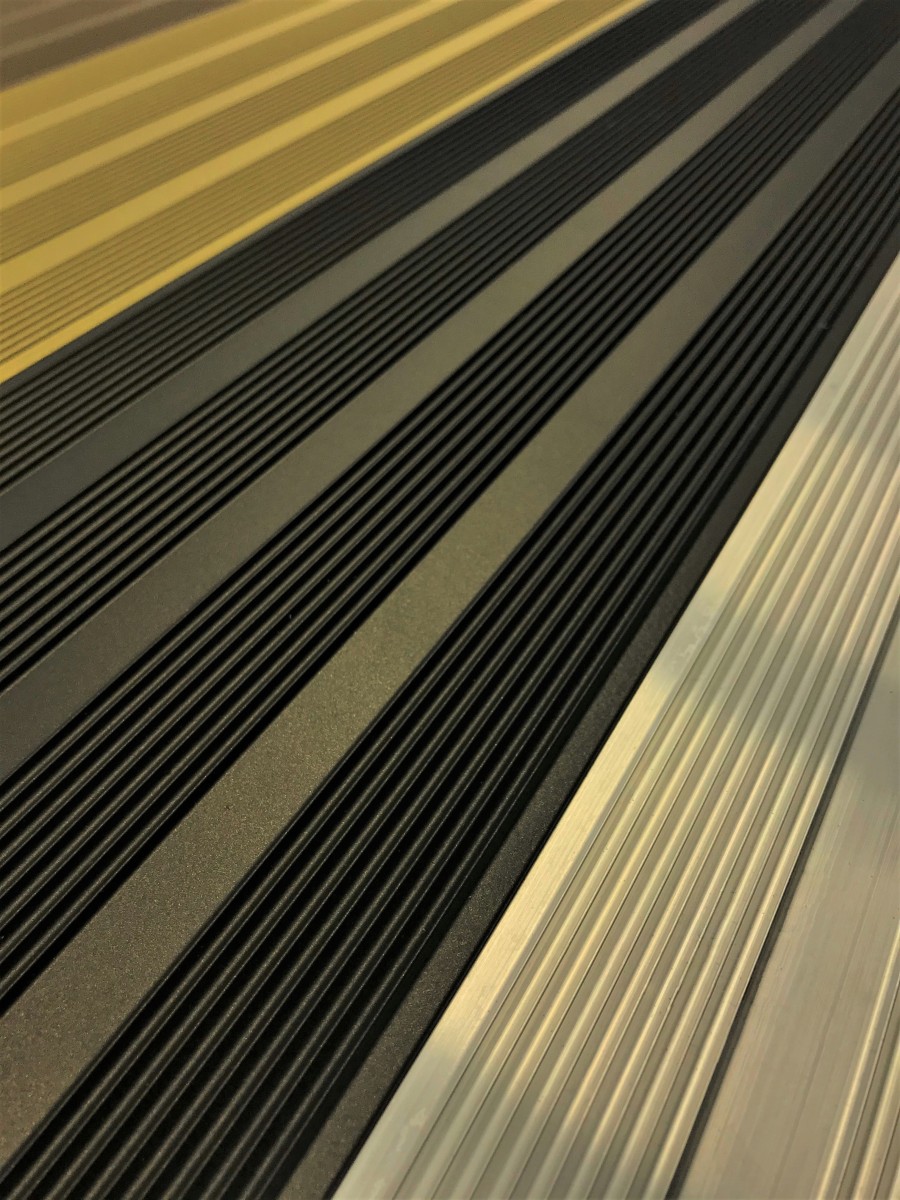

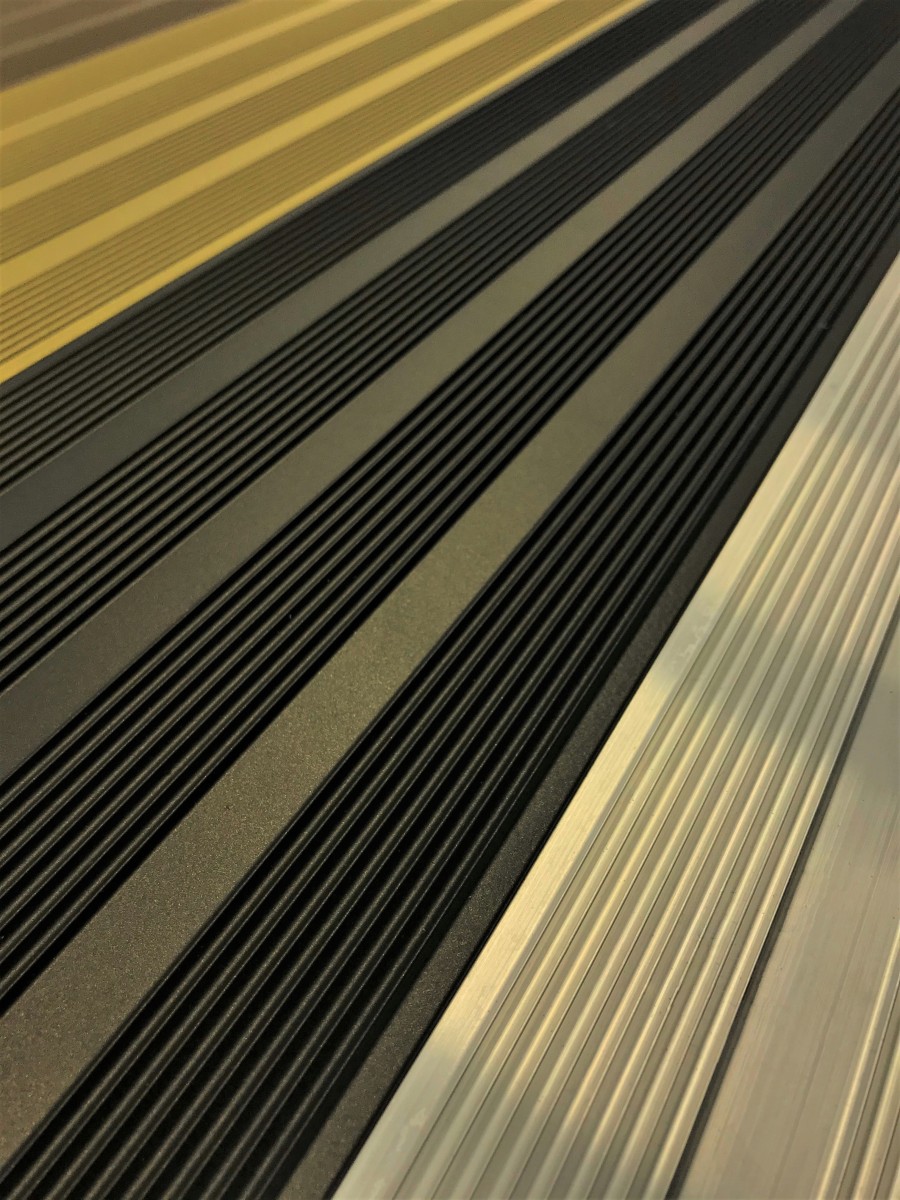

Modular products have another invaluable advantage in the context of these refurbishment projects: suppliers with technical expertise can design and manufacture systems that offer ready-made, certified compliance with the regulations and guidelines introduced since 2018. At Neaco, we manufacture aluminium balcony decking, balustrades and full balcony solutions which are Fire Rated and meet all requirements, both legal and advisory. Flooring material is the element which most commonly needs replacing – many balconies on existing buildings still include traditional timber decking – and our aluminium systems offer an A1 or A2 Fire Rating which meets the standards set out in the 2018 Building (Amendment) Regulations.

Offering that instant compliance has provided peace of mind to many local authorities and building owners seeking a straightforward solution to their refurbishment needs. With an incentive to act fast, they value suppliers that can deliver end-to-end with equal speed.