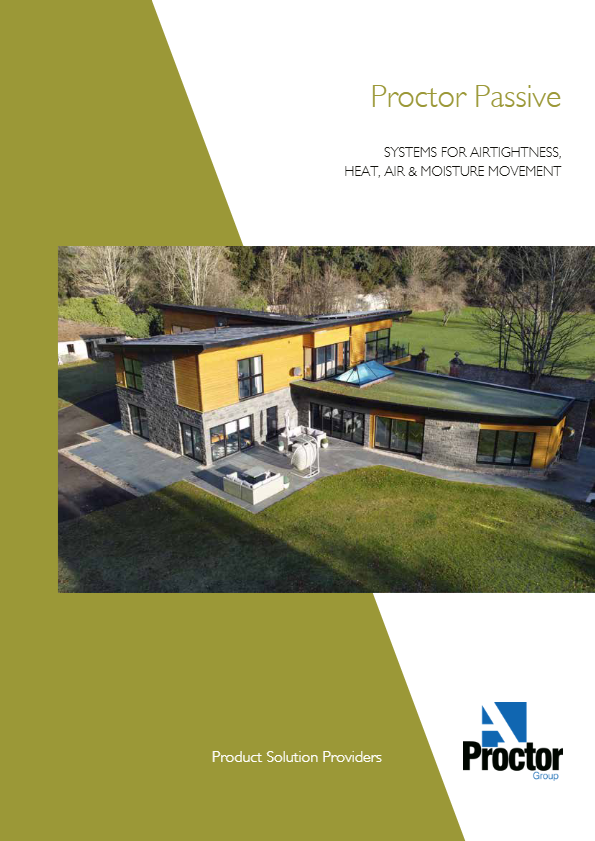

As the UK looks towards offsite and modular construction to address the housing supply shortage, manufacturers will seek to install high-performing air barrier systems as an essential component in achieving the most effective means of controlling and reducing air leaks.

Air leakage through cracks, gaps, holes and improperly sealed elements such as doors and windows can cause a significant reduction in the performance of even thermally insulated building envelopes. As thermal insulation requirements have increased over the last few years, the proportion of energy lost through air leakage has become more evident. The ever-increasing thermal insulation required will, however, be rendered largely ineffective unless the airtightness of the structure itself is addressed. Air leakage greatly reduces the effect of thermal insulation; therefore if energy efficiency is to be improved within buildings, this is the most critical area to focus on.

In addition to improved insulation, energy efficient heating systems will also be ineffective if warm air can escape the building and cold air can seep in. This is reflected in the fact that total space heating costs in an airtight construction may be considerably less than in a leaky one.

Airtightness and offsite manufacture

The two main ways to achieve airtightness in the building envelope are internally or externally, or in other terms, “inside of the services zone’ or ‘outside of the services zone’. In offsite manufacture, the use of traditional internal air barriers can be more complex and costly to install, due to the need to accommodate building services such as electrical, lighting, heating and drainage systems. An internal air barrier is only as good as it’s installation. If all the service penetrations are not adequately sealed, performance will be compromised.

For many years, external air barriers have been commonly used in North American building design and construction. By moving the air barrier to the external side of the structural frame, external air barrier systems such as Wraptite® from A. Proctor Group allow for an almost penetration-free airtight layer, which can be installed faster and more robustly. This offers an effective but simple system comprising a self-adhesive vapour permeable air barrier membrane, plus vapour permeable sealing tape, Wraptite Corners and Wraptite Liquid Flashing, and provides effective secondary weather protection while preventing trapped moisture and air leakage. Far simpler than internal options an external air barrier system like Wraptite will maintain the envelope’s integrity, with less building services and structural penetrations to be sealed, and less room for error.

A simple, fast airtight installation

The traditional forms of VCLs and airtightness membranes will often require mechanical fixing. In the case of timber structures using steel staples, and on concrete using a separate double-sided adhesive tape. The self-adhered nature of Wraptite allows for a simple and fast installation process, minimising the use of additional sealants and tapes, and requiring no specialist contractors to achieve a robust result. This one-step solution provides both a damage-resistant air barrier layer and effective secondary weather protection in one installation process, allowing a wind and watertight envelope to be achieved more quickly than using traditional methods.

TopHat incorporates Wraptite into the design

One of the UK’s leading modular housing manufacturers TopHat has successfully incorporated Wraptite into the design of its high-quality timber-framed homes.Wraptite is a patented external air barrier membrane system, which offers manufacturers and designers of modular and off-site buildings the ability to reliably and comfortably exceed current airtightness requirements. Wraptite is the only self-adhering vapour permeable air barrier certified by the BBA and combines the important properties of vapour permeability and airtightness in one self-adhering membrane.

The A. Proctor Group provides a range of high-performance membranes to address the requirements of heat, air, moisture management within the building element, and provides comprehensive guidance to designers and manufacturers of offsite construction using modelling & analysis tools to ensure compliance and guide on best practice related to DfMA.