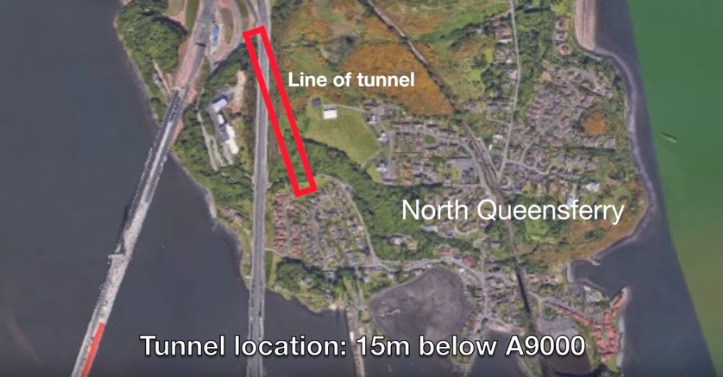

When a disused Victorian-era railway tunnel in Scotland was shown to be degrading, threatening the roads above, the structure needed to be made safe. A key element of the challenging infill solution was provided by an advanced hydrocarbon and chemical resistant barrier.

The St Margaret’s Head Tunnel was originally part of the Dunfermline to North Queensferry railway line and lies under the northern approach to the Forth Road Bridge.

Amey, the Forth Bridges Operating Company, determined that preventative measures needed to be taken to ensure the tunnel’s structural integrity. The tunnel, which is 420m long, 4.3m wide and 5.1m high, had been sealed off, with only two vertical shafts at either end for access points. The Amey engineers decided the best solution would be to fill the tunnel with a low cost infill material.

Expanded polystyrene (EPS) blocks – strong, durable and easily cut to size for handling in the shafts and tunnel – were the answer. However, hydrocarbons and volatile organic compounds (VOCs) can damage EPS materials, so the blocks needed to be protected from these by-products of oil and diesel contamination.

Powerbase VOC, a technologically advanced barrier membrane, provided what the project and site demanded. Manufactured by Industrial Textiles & Plastics (ITP) of North Yorkshire, Powerbase VOC has been tested to EN ISO 15105-2 for a large range of harmful and is BS 8485: 2015 + A1:2019 compliant. Performance data demonstrates the barrier membrane’s superior resistance to challenge chemicals. Both the EPS blocks and Powerbase VOC were supplied to Amey by Cordek Ltd. A video showing the progress of this exciting installation can be viewed on YouTube.

Once the body of the tunnel was lined with Powerbase VOC and filled with EPS blocks, the two access points were filled with concrete to seal the access shafts. The safety of the busy roads and buildings above in South Queensferry is now secure for the future, but should it ever need to be reopened, the blocks can easily be removed.

ITP manufacture an extensive range of temporary containment materials, building membranes and gas barrier membranes. The company has specialist expertise in chemical resistant and flame retardant technology.