Grimsby, United Kingdom- July 6th, 2015- This press release compares carbon footprint of the formwork system developed and used against traditional Timber and custom made formwork system.

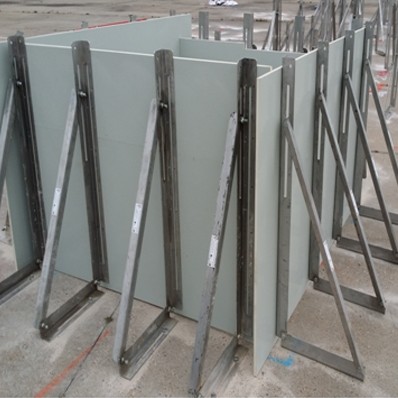

Fast Form Systems Ltd is a rapidly expanding formwork & shuttering system available for hire & sales which is taking the United Kingdom by storm with contracts from Balfour Beatty on the London underground, Network Rail, the MOD 21st Regiment the Royal Engineers, Environment Agency and on the new Olympic Stadium seating conversion to name but a few.

Fast Form promotes the fact the system is lightweight and also has a very low carbon footprint, so recently we put our methods to the test with help from the University of Grimsby. The examination would compare Fast Form formwork against traditional timber & plywood formwork, these would then be calculated by the amount of CO2 embodied in materials and the transportation process.

The amount of CO2 embodied in these materials used in both systems is taken into account and is considered per kilogram and multiplied by the weight of the unit. The amount of carbon embodied after 100% recycling has also been considered this amount is then added the total CO2 embodied in each unit. This figure then can be used to calculate the embodied carbon amount for a single year.

“The results show a significant difference between the embodied CO2 amounts in each of the systems during the unit lifecycle. It is clear that the amount of carbon embodied in Timber and Plywood brackets are up to 10 times more than the amount of the Fast-Form brackets yearly so multiplied by the expected 15 year lifespan of the brackets offers a significant reduction. Even using timber ply with Fast Form instead of Plastic Ply it still offers a huge savings over traditional timber methods with timber using at least 5 times more carbon per year than the Fast Form brackets with Timber ply”,

In Conclusion, Fast Form Systems Ltd will improve your safety, reduce your carbon footprint and save you time and money, typically 50-60% cost and time savings can be achieved against traditional methods and traditional methods use up to 10 times more Carbon, using Fast Form can also lower your Carbon Footprint by 90%.

The full Carbon Study is available at http://www.fastformsystems.com/wp-content/uploads/2012/09/Carbon-Footprint-Report-Fast-Form.pdf