Aluminium is a strategic raw material with distinctive characteristics that enable repeated recycling without compromising its original properties. Recycling aluminium is a highly effective method for reducing carbon emissions throughout our value chain, requiring only 5% of the energy necessary for primary production. Additionally, it significantly enhances the UK’s resource efficiency and strategic autonomy. Nevertheless, the UK and Europe continue to export valuable aluminium scrap at record rates, with 1.2 million tonnes exported in 2023 alone.

Scrap exports primarily consist of energy and secondary raw materials. Given the UK’s high energy costs and resource scarcity, retaining this strategic material within the UK presents a mutually beneficial opportunity for its competitiveness, sustainability, and decarbonisation efforts.

The CAB Closed Loop Recycling Scheme offers significant sustainability benefits by promoting the recycling of aluminium within its specific alloy grades. By ensuring that aluminium scrap remains within closed, well-defined material streams, the scheme minimises the mixing of alloy grades that can reduce the overall value and performance of recycled material. This quality-controlled approach not only helps maintain the inherent properties of the metal through multiple recycling cycles but also saves energy and reduces greenhouse gas emissions. The environmental benefits are substantial, as the initiative supports a circular economy, diverts waste from landfills, and contributes to the reduction of embodied carbon in construction projects.

In addition to environmental advantages, closed loop aluminium recycling also drives economic benefits. By lowering energy and raw material costs, manufacturers can achieve greater efficiency and cost-effectiveness, enhancing their competitiveness in global markets. This recycling approach also spurs local job creation in recycling and manufacturing sectors and fosters innovation in material processing and waste management. Overall, adopting closed loop recycling not only contributes to a greener economy but also supports long-term economic stability and growth in the UK.

Beyond its environmental advantages, the scheme delivers practical operational and economic benefits for participating organisations. By requiring Members of the CAB Closed Loop Recycling Scheme to collect and sort aluminium scrap accurately using modern technology such as handheld XRF analysers, the scheme enhances the traceability and quality of scrap material, ensuring it is reprocessed into the same high-quality alloy grade. This systematic approach not only increases the resale value of the scrap but also strengthens the sustainability credentials of suppliers and contractors in a market where proof of low embodied carbon is becoming increasingly important. As more companies and main contractors adopt such practices, participation in the CAB Closed Loop Recycling Scheme can serve as a differentiator, demonstrating commitment to best practices in sustainability while optimising resource recovery.

Aluprof UK are proud to announce that they have recently joined the CAB Closed Loop Recycling Scheme and can offer its benefits on any upcoming projects where main contractors wish to reduce their carbon impact on new construction.The work is ongoing to reduce carbon embodiment in all aluminium production.

Grupa Kety, Aluprof UK’s parent company, have already done a great deal of work in primary aluminium production, where carbon embodiment has been significantly reduced. According to a 2020 White Paper, ‘Low-carbon Aluminium, Solution for Sustainable Construction & Renovation’, primary aluminium from China, which has been as high as 20 CO2e/t (carbon dioxide emissions equivalent per tonne of aluminium), drops now to an average global production output of primary aluminium of 16.7 CO2e/t. ‘Low-carbon’ primary aluminium in 2020 on average was reported as releasing 6.67 CO2e/ per tonne of aluminium.

Today, whilst ‘low carbon’ primary aluminium is not formally defined, a carbon footprint of less than 4 CO2e/t is a common reference, representing the very lowest achievable with currently available technologies. This carbon footprint is often referred to as ‘Cradle to Gate’. The global aluminium industry has achieved this figure through the use of renewable energy sources such as hydro power and other renewable technologies. Further reductions will soon be possible as the industry begins to adopt emerging green hydrogen technology during the production cycle.

The amount of recycled aluminium utilised worldwide, often termed secondary production, has shown little variation, maintaining a range of 31-33% since 2000, with a notable peak of 34% in 2019. Given aluminium's high market value, collection rates tend to be robust; in 2019, collection rates for new scrap (pre-consumer) surpassed 95%, whilst those for old scrap (post-consumer) were just over 70%. It is vital to continue to improve the collection of post-consumer scrap, as recycling this material is significantly more energy-efficient and this is where the CAB Closed Loop Recycling Scheme is so important.

According to a statement made by the Aluminium Stewardship Initiative (ASI) in February 2022, “Under a 1.5 degree scenario, the aluminium sector must reduce its GHG (Green House Gas) emissions from over a billion tonnes of CO2e to around fifty million tonnes by 2050. This is less than one-twentieth of current emissions.” LowCarbonKety, a subsidiary of Grupa Kety, Aluprof’s parent company, offers aluminium billet with an impressively low carbon footprint of 2.9 kg of CO2 for every kilogram of aluminium produced. These low-carbon products are composed of up to 75% post-consumer scrap, around 10% pre-consumer scrap, and a minimal amount of primary aluminium, all manufactured using renewable energy sources.

It is important to consider that extended lead times may affect project timelines, potentially resulting in additional carbon costs. Conversely, selecting low-carbon products, including aluminium, may yield certain BREEAM credits for the project. These factors underscore the uniqueness of each project, necessitating a tailored approach. Engaging product suppliers during the early design phase is essential to explore viable options. Aluprof's experienced design team is available to assist in identifying the most suitable aluminium sources and systems for any project during your specification process.

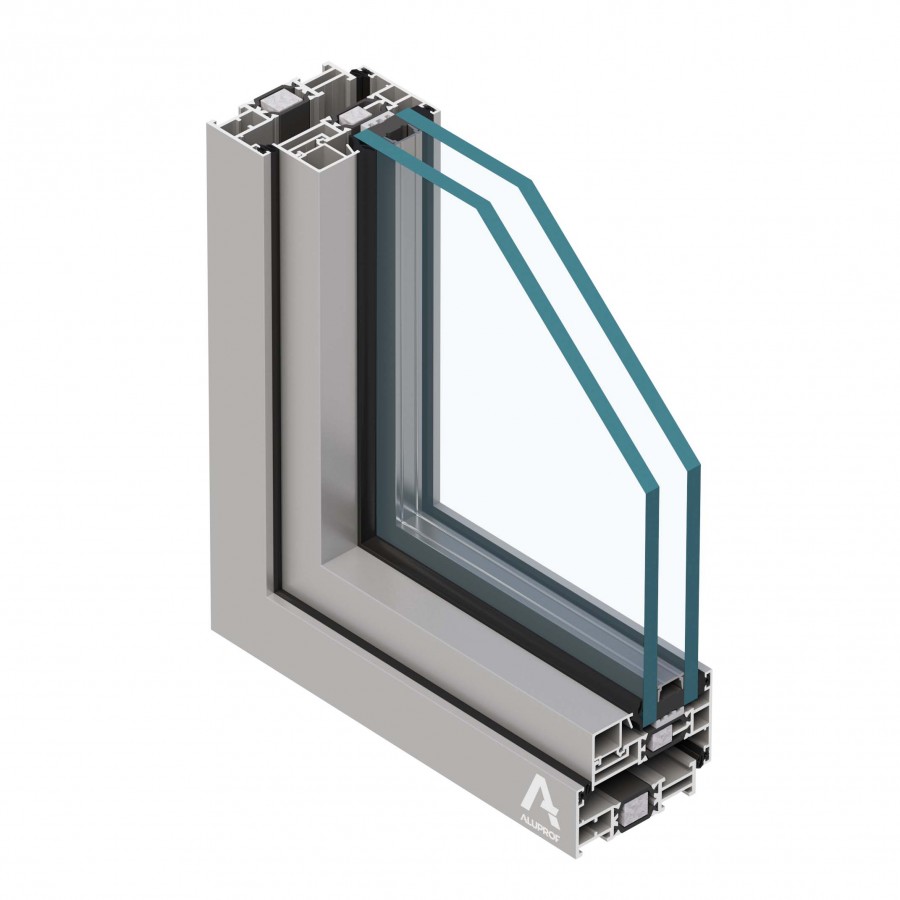

Whilst it is crucial to reduce ‘Embedded Carbon’ in profile supply, here at Aluprof we take a holistic approach to carbon reduction by also reducing ‘Operational Carbon’. Aluprof aluminium windows and doors play a crucial role in decreasing operational carbon emissions by improving the energy efficiency of buildings. The exceptional thermal insulation properties of our systems reduce the need for heating and cooling, thereby lowering energy consumption and the related carbon emissions. Additionally, the durability and minimal maintenance needs of aluminium contribute to the longevity of these systems, further reducing their environmental footprint. By opting for aluminium windows and doors, buildings can attain a more sustainable and reduced carbon footprint.

Aluprof UK have been supporting specifiers in the UK and Ireland for over fifteen years with advanced systems that include, high performance windows doors and facade systems. Many UK and Ireland based fabricators and installers supply these systems and are on hand to offer surveys and cost analysis as to what improvements can be made with likely paybacks. Further information about systems and specification support is available through the company website at aluprof.co.uk or direct from their UK head office in Altrincham by phoning +44 (0) 161 941 4005.