A new six-minute video from the NBBA (National Blown Bead Association) demonstrates the clear advantages of airpop over traditional mineral fibre cavity insulation for all types of new build properties.

The video (http://www.eps.co.uk/news/airpopvideo.html) shot on real residential building sites in England and Northern Ireland states that the speed, simplicity and long-term effectiveness of blowing airpop (expanded polystyrene) beads into cavity walls enables building and construction companies to achieve lamda values which are superior to other insulation - allowing Part L of Building Regulations to be easily met or exceeded.

The video also shows how the compact, on-site installation process carried out by an NBBA member ensures fast coverage in all areas of the most complex cavities and can easily be scheduled so as not to interfere with other trades on site.

According to the video, produced by the EPS group of the British Plastics Federation, airpop is a ‘best in class’ insulation material which offers long-term performance because it also overcomes problems of settlement encountered with lesser materials.

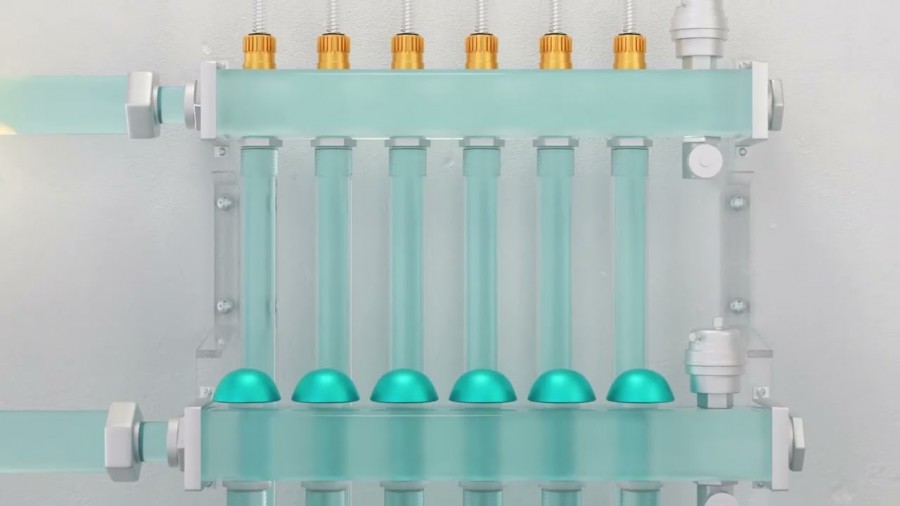

The unique nature of the fast-flowing beads mean they fill from the smallest to the widest cavities as well as reaching complex internal geometries which demand extreme, high insulation performance. A special test rig in the video is used to show that the beads flow at high speed like liquid into every part of the cavity. They also seek out the all the gaps and imperfections in the cavity. In minutes, every void around services, joists, conduits, doors, windows and other internal structures is completely filled with millions of beads to ensure there are no cold spots. After each cavity is filled, the beads settle immediately and become bonded together to form a virtual solid layer of insulation which is stable - yet allows the cavity to breathe as intended.

The video also tackles the issue of water ingress which can cause damp problems over time when moisture is trapped liked a sponge in fibrous materials. It graphically shows the millions of tiny spheres allowing the safe and effective dispersal of any moisture rapidly to the ground rather than creeping laterally to inner walls.

Blown bead insulation requires smaller and fewer drill holes in the internal walls of the property. These are made directly into the cavity before the walls are finished and plastered. There is also none of the residual scrap left behind by other systems – so airpop bead eliminates waste and the cost of waste.

NBBA expert installers use specialist equipment which is completely self-contained and can be used in all site conditions. They also give the backing of BBA approved certification. Airpop is 98% air captured during manufacture in a polystyrene matrix.