Lovell Purbeck, a specialist in Purbeck and Lias natural stone, has taken a major step toward self-sufficiency and reducing its carbon footprint by generating its own electricity and implementing ‘green’ processing methods. The installation of a 47KWp photovoltaic generation system generates 100% of the company’s electricity requirements at its Bowdens Quarry (Lias), whilst at Downs Quarry (Purbeck) a 50KWp system meets 20% of the site’s electricity needs.

At Bowdens Quarry, Somerset, the company’s most recent acquisition, the 47KWp system powers the newly installed guillotine and finishing plant. To date it has generated over 12,000KWh of electricity since being commissioned at end of 2011, with over 11,000KWh being fed directly into the National Grid as surplus.

Installed on the roof of the company’s new tile processing factory at Downs Quarry, on the Isle of Purbeck, the 50KWp system contributes toward the running of the new primary saws and tile processing equipment. Since commissioning in November 2011 the system has generated over 15,000KWh, contributing to 20% of the site’s usage, and power generated out-of-hours is fed back into the National Grid.

With an investment of around £230,000, Lovell Purbeck is expecting payback in less than 10 years. Managing director, Simon Hart comments: “With a life expectancy of 20 – 25 years this equipment really does stand the test of time, and with payback achievable in under 10 years, it is a sound investment for the business.”

Over the next 12 months Lovell Purbeck will continue to monitor and measure the results of the PV installation and assess its impact on the reduction of the company’s carbon footprint; a figure that can then be attributed per tonne of extracted stone.

‘Green’ Water Usage

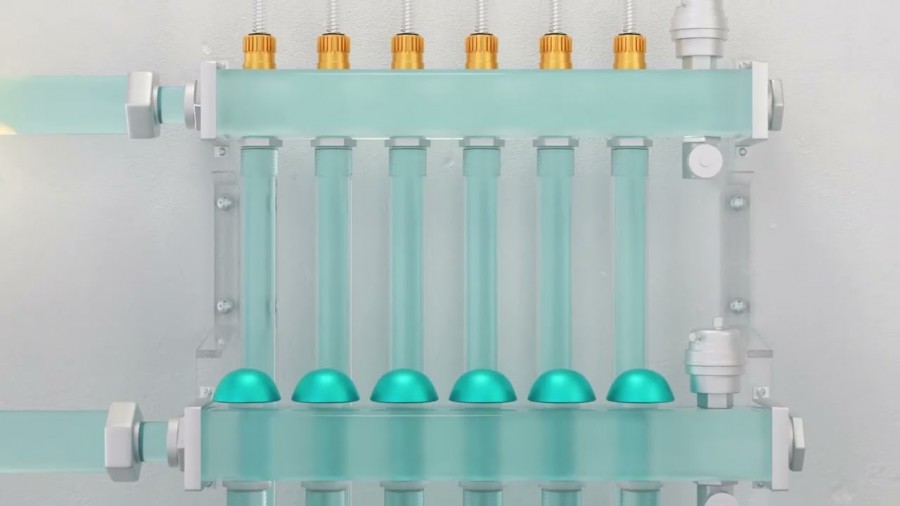

Lovell Purbeck has also invested in a water management system at its Downs Quarry site, including rainwater harvesting system and a water cleaning and recycling unit. With the addition of the tile line and new cutting equipment the site can use as much as 1,000L of water per minute. The water recycling system includes a filter press that removes the water from the production waste, resulting in ‘cake’. This lime-based by-product is then used for grassland improvement on restored or agricultural land whilst the cleaned water is reused within the tile factory.

Award-winning Facilities

Due to its dedication and commitment to this green initiative, Lovell Purbeck has been named the ‘Workshop/Premises’ award winner at this year’s Natural Stone Awards Sustainability Day, hosted by the Stone Federation Great Britain.

The judges commented: “Lovell Purbeck has been farsighted in adopting this approach to energy efficiency. Not only making their commercial operations more economic and sustainable, their range of available products capitalise on the uniqueness of the local materials to help ensure that these will continue to contribute to the long-term sustainability of the indigenous architecture, streetscapes and appearance of the supplied region and beyond.”

The Lovell quarries on the Isle of Purbeck produce a wide range of limestones including blue and white-buff colours while, Bowdens Quarry, Somerset, has the only consented reserve of White Lias Limestone in the country.