David Helsby, President of RadTech Europe, explores this very relevant process.

Architectural fittings and infrastructure, flooring, furniture and appliances may seem to have little in common except their intended final location – a building.

But they are, in fact, linked by a process in their manufacture that is lean, green, and cost-effective: energy curing of adhesives, resins, and other coatings.

Four major factors drive most industrial business today: manufacturing efficiency and speed; saving costs; environmental and health and safety concerns; and profitability.

That is certainly so in the areas of architectural construction and interior fittings.

Finished goods and construction components – which can often be extremely large flat panels – must incorporate long-term durability and weatherability in their make-up. Traditional routes to achieving such functional finishes in the manufacturing process are still widely employed – but they are slow and not very energy-efficient. It is therefore hardly surprising that energy curing (drying or setting) of coatings and finishes of all kinds is increasingly the preferred technology in this industry.

Energy curing delivers outstanding performance in an extremely wide range of application areas, creating durable, elegant finishes on architectural panels, glass, doors, wooden and laminate furniture and flooring – even entire industrial floors and car parks.

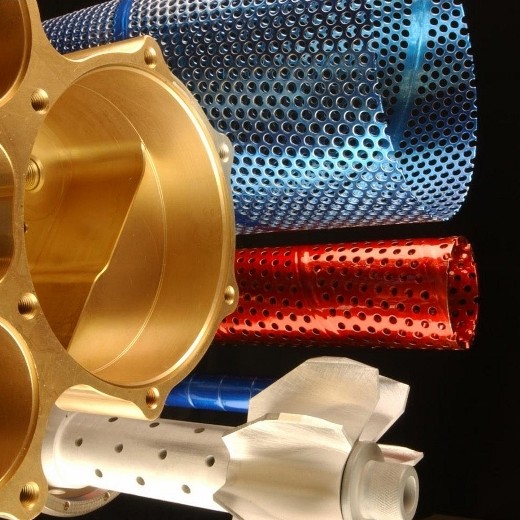

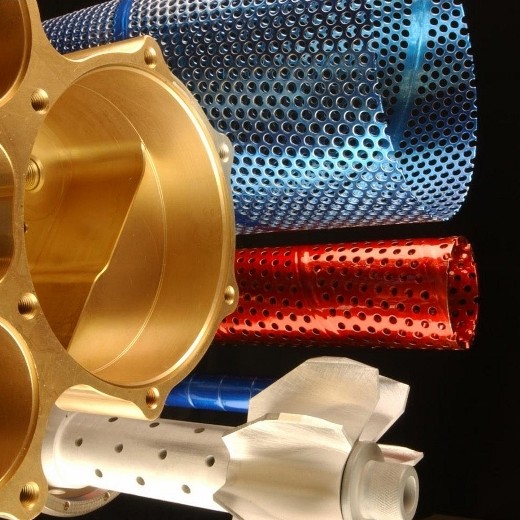

It also provides an anti-fingerprinting coating for stainless steel, particularly for domestic appliances, as well as protective, anti-corrosion coatings for pipes.

As our need and desire to optimise environmental credentials without penalising profitability increase, manufacturers throughout the value chain - from raw materials to finished furnishings and fitments - are increasingly looking at energy curing as a considerable contribution to achieving the answer.

Energy curing’s core competence is speed and efficiency. It may take one of two paths – using UV (ultraviolet) light or an electron beam (EB), and its definition of a ‘coating’ is broad. As well as providing a glossy, scratch and slip-resistant finish for wooden flooring panels or for painted surfaces, it also involves drying inks – fast -- on a printing substrate, and sealing a haptic varnish coating to the cover of a smartphone.

UV curing, using photoinitiators (and latterly LED technology), is the choice for flat surfaces, and EB - with higher initial investment and running costs - for high-volume, three-dimensional, and heat-sensitive projects. Both pathways are energy-efficient, and EB in particular offers reduced CO2 emissions. They can also actually enhance and optimise the performance and quality of the coatings they cure while dramatically reducing the lengthy drying times and heat/energy requirements of traditional curing methods.

Both end users – professional and amateur builders – and component manufacturers themselves can benefit from energy-cured finishes on the products they employ, especially where product performance is critical. In building and construction, there is increasing use of plastics as structural components – particularly for roofing panels and windows. Such large, flat surfaces are ideally suited to UV curing, which instantly and cost-effectively delivers abrasion, scratch, and weather-resistance and enables the manufacturer to move the panels immediately out of the factory and into packaging and storage.

Glass

UV curing can also add thick laminate under-layers to glass panels to create shatter-resistant safety glass, protecting both people and property. Curing photovoltaic solar panels produced using the inkjet process is another growing market for energy curing.

It is essential that the surface of a parquet, vinyl or marble floor is properly sealed to deliver a scratch and stain-resistant anti-slip finish which, indeed, may need to be repaired and restored as its working life moves on, or as accidents happen. An energy-cured coating can deliver this, throughout the floor’s life, using offline UV equipment, which may even be hand-held. Large offline UV units are also responsible for creating entire floors in new factory buildings and car parks.

Decorative and protective finishes on items of furniture for the home, and for doors, are two more long-established and popular applications for energy curing. This is a market which continues to find new and creative ways of adding value for its consumer customers.

Whatever the requirement in the context of architectural and furnishing components, the expert international supply chain that has built up since the energy curing technology made its first appearance 40 years ago will create the perfect chemical formulation for any given application, and any desired surface finish.

UV and EB curing will deliver energy savings over traditional drying methods; an instant cure, saving valuable time; improved environmental credentials and reduced greenhouse gases; and a key, proven element in modern best practice manufacturing that is still opening up new markets.

RadTech Europe, the association promoting the technology, represents the major companies across the EB and UV value chain.