Yuliya Nam-Wright, Head of Sustainability at Bostik UK, outlines the sustainability measures the flooring industry is currently taking – and how they can help with your environmental targets

Sustainability is no longer a ‘nice to have’ – it’s a necessity. With specifiers in construction facing growing pressure to meet tightening regulations, it has never been more important to balance cost and quality with environmental performance.

So, what are manufacturers like Bostik doing about sustainability – and how can it help you?

The importance of EPDs

Offered by most manufacturers, Environmental Product Declarations (EPDs) provide valuable information on a product’s environmental credentials and include data on recyclability and end-of-life disposal options. This helps you make informed, evidence-based decisions on which products to use and achieve green building certifications like BREEAM and LEED.

For example, you may be choosing between two flooring adhesives that perform equally well at a similar price. A look at their respective EPDs might reveal that one has lower VOC emissions or better recyclability – making the decision an easy one.

Embracing innovation

It’s not just about the product itself, but also the packaging it comes in. Over the past decade, the flooring industry has made strides to innovate and reduce packaging waste. Adhesive buckets are now often made with PCR plastics, reducing reliance on virgin materials, for example, while many smoothing compounds are being introduced as one-part products in favour of the traditional ‘bag and bottle’.

It's a good idea to prioritise flooring manufacturers that offer sustainable packaging, as this will lower carbon footprint, boost the sustainability credentials of your projects, and satisfy demand from clients and regulatory bodies for greener practices across the supply chain.

Product innovation

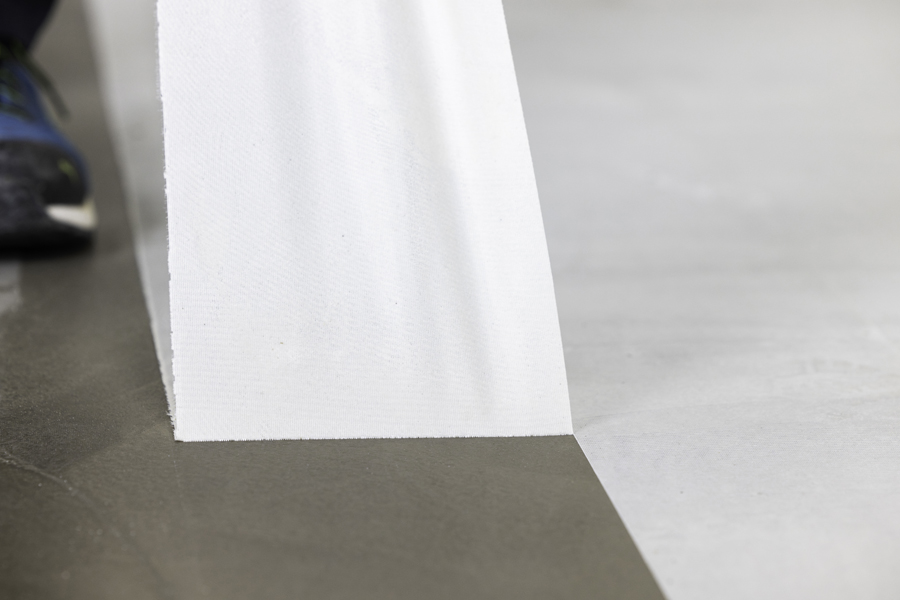

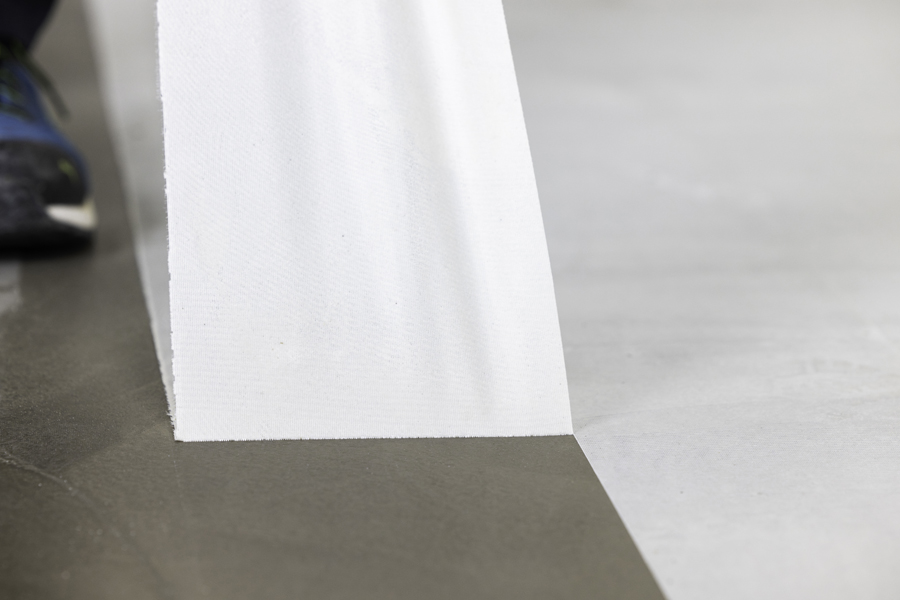

Adhesives are designed to form strong bonds between floor coverings and subfloors, making it difficult to separate these layers at the end of a product’s lifecycle. Traditional adhesives often leave residues on both surfaces, contaminating the flooring material and rendering it unsuitable for recycling. Removing adhesive contamination requires additional processing steps, such as mechanical scraping, chemical treatment, or thermal cleaning. This can increase the cost and energy use of the recycling process and limits the economic viability of recycling flooring materials on a large scale.

‘Reversible’ adhesives such as Bostik R3BOND solve this issue by allowing for easier removal of floor coverings at the end of life, without damaging the materials. R3BOND enables easy installation and removal of floor coverings such as vinyl and LVT with no residue, even years later, allowing the flooring to be recycled at the end of its life. Once removed, it leaves behind a subfloor that requires next to no preparation, meaning renovation times and carbon footprint are significantly reduced.

By embracing the latest sustainable innovations in flooring, you can reduce your environmental impact, meet green building certifications, and contribute to a more sustainable built environment.

Bostik is part of Arkema, a global leader in speciality chemicals. As a supporter of the United Nations Global Compact, Arkema has committed to the 2030 Agenda for Sustainable Development. To find out more about its range of flooring products, visit https://bostik-profloor.co.uk/.