Elzbieta Kantor - Aluprof Operations Director

What is ‘vertical integration?’ and why is it important to the specifier when choosing suppliers? Vertical integration for any business is gaining control of upstream processes, normally by bringing them in-house to gain more control and consolidate costs. It is important from a specification process viewpoint as it offers many advantages in ease of supply, quality and costs.

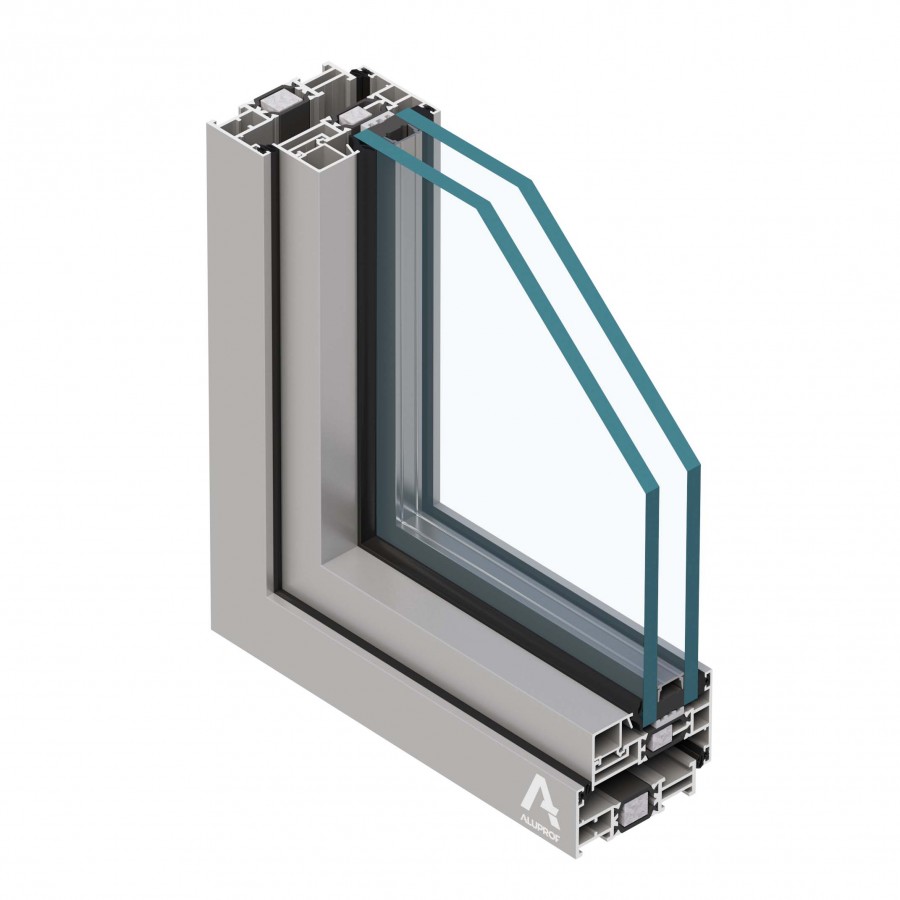

An architectural aluminium systems company designs windows, doors, curtain wall systems and other products for use in building construction. These products are supplied in system form to fabricators and installers who manufacture and install under contract. Each system is extensively tested and carries the appropriate standards and performance levels for various applications.

When single systems are shared among several fabricators, the cost of development, testing, and updating is divided among them, with the systems company handling these tasks.

Many systems companies supply warehouse stock to their customers for ‘off-the-shelf’ windows, doors and curtain walls. As projects become more complex and expect higher performance levels, a systems company that looks to become more vertically integrated offers many advantages to the specifier. Vertical integration can include the ability to smelt aluminium, the design of dies to extrude profiles, inserting thermal breaks in profiles and offering finished profiles, either powder coating or anodised.

Only a few of the leading systems companies operating across the UK and Europe are vertically integrated. Having control of each process that completes a window door or curtain wall system helps limit risk. Between separate suppliers, such as between an extruder and a systems company, conflict can arise when the extrusion supplied does not meet expectations from the systems company, for various reasons, this poses risk, both on supply time and costs.

Following extrusion, main profiles often require thermal breaks to be inserted by first knurling the profile, inserting the thermal break, often made of polyamide along with additional insulation materials and then rolling the profile to create a single section. Being able to integrate a thermal break also allows the systems company to develop special designs of polyamide profiles that can enhance the performance both in thermal and weathering characteristics. In-house finishing of profiles further enhances system allowing for single or bespoke dual colour profiles to be created. All systems companies now offer QUALICOAT powder coated profiles as a standard which is recognised globally. Powder coating all profiles in-house reduces both time and transport requirements.

Vertical process integration can improve safety in the workplace by removing many of the operations where transport is required between businesses. Fewer loadings and unloading of profiles not only reduce potential health and safety issues, but also reduces the risk of profile damage in transit. A further consideration is the reduction in packaging need when profiles require protection when shipped between companies for processing.

Reduced handling of profiles allows for optimisation of processes and improvement in logistics. For example, batches of profiles of various sizes can more easily be processed economically rather than having to opt for the advantages of scale to save costs. With the reduction of minimum process quantities comes the benefit of speed of production thereby reducing order lead times for customers.

With the advantages of vertical integration mentioned above, a further benefit to the specifier is a reduction in carbon emissions. Reduced handling requirements and carbon miles automatically save energy, but linking the processes can also allow for further reductions to be accommodated when processing in a single location. With less handling and closer communication up and down the supply chain can lead to a more consistent profile quality. A single company that controls the entire process from start to finish has a vested interest in reducing wastage, minimising energy use and providing an optimised system, often bespoke on a project per project basis.

Aluprof, as a vertically integrated systems supplier encompass the development and production of various systems for applications in a wide range of building projects. In the UK & Ireland Aluprof UK offers local support to specifiers and contractors. Aluprof UK place more emphasis on flexibility with their ‘Tailored Solutions’ approach. For example, by having an experienced and extensive design team in Poland, Aluprof UK can quickly create bespoke profiles to suit any project. With an experienced design team in the UK Aluprof will collectively work with architects and fabricators to agree a solution which carries Aluprof’s warranty into the project which is passed onto the client.

All customers in the UK & Ireland enjoy weekly deliveries direct from Aluprof’s distribution centre based in Poland. Delivering directly to the customer reduces lead times, reduces handling damage and saves carbon, compared to double-handle project-specific material, such as delivering to a UK warehouse and then onto a further delivery vehicle for final delivery. Aluprof also ship orders complete, which enables the fabricator to schedule fabrication from delivery, rather than having to check and wait for all the materials to arrive. Both these approaches to supply, significantly reduce lead times allowing the fabricator to get products installed on site quicker and hopefully help improve cash flow throughout a contract.

Aluprof also recognised that not all fabricators can put on extra shifts to meet busy times as production facilities often utilise a lean working ethic to maintain competitiveness. To assist fabricators, Aluprof introduced a fabrication facility in Poland that can support fabricators in manufacturing some of the supplies at their request. This has proven to be a real benefit to customers who contract and often use this facility to manufacture the more difficult constructions required on a project.

Value Management, which encompasses Value Engineering, looks at every process from order through to completion. To begin with, an overview of the complete project programme is needed, with each of the processes and deadlines for completion itemised. It is at this stage that options are discussed. One of the obvious choices is that of the systems to be used for the windows, doors or facade. As ahigh end systems company, Aluprof offer their systems in various designs to meet the exact needs of the building. An example of this can be seen in Aluprof's popular MB-SR50N Curtain Wall system, far from being a single system there are many options to choose from, these include various insulation levels, capping options or structural arrangements, each choice represents a cost or a cost saving. It's a little like specifying options on a new car taking the base model of choice as a starting point.

A further consideration is the optimisation of aluminium profile cutting. To reduce wastage on fabrication, profiles can be extruded to special lengths which offer high levels of cutting optimisation which in turn reduces material waste, which then reduces costs. These are just some of the important issues that are reviewed in the Value Management process which ensures that the completed project performs exactly as specified and perfectly meets with the clients' expectations.

So, from specification through to installation, the Aluprof team in the UK ‘partners’ with specifiers and customers to ensure that system supply is value managed, minimising cost and carbon footprint. Aluprof UK believe this ‘Value Management’ strengthens the relationship with customers who then often request Aluprof to partner them on projects that they have secured.

Aluprof are proud to be one of Europe's largest aluminium systems companies. Specification support is available through the company’s website at aluprof.co.uk, directly from their UK head office in Altrincham or from their London office at the Building Design Centre by phoning +44 (0) 161 941 4005.