- Location: London

- Project size: 23,000 sq m

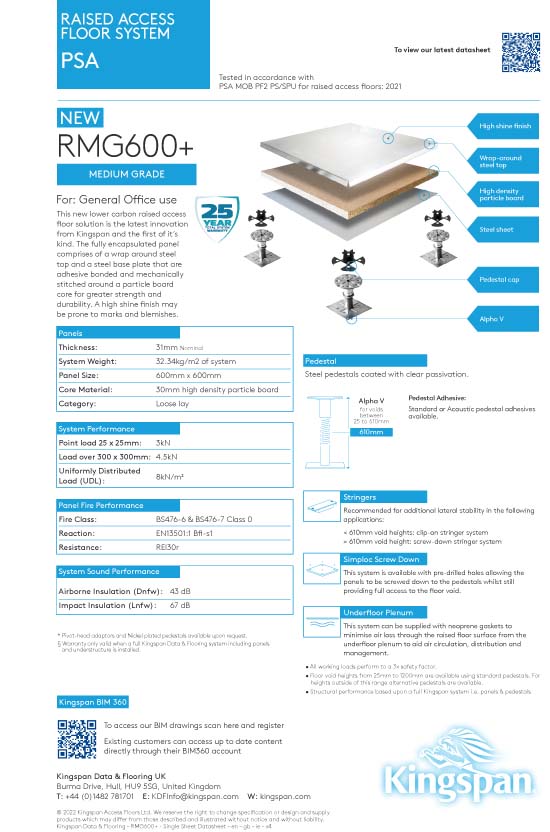

- Product: RMG600 and Kooltherm

- Main Contractor: Sir Robert Mcalpine

- Architect: Allford Hall Monaghan Morris

- Photography: Timothy Soar

A Sustainable Project from Start to Finish

At Kingspan, we've always been synonymous with quality, both for our products and the level of service we provide. Sometimes however, we are required to go beyond the call of duty and complete a job in double-quick time, while still working to the high standards that have helped make our name.

This was the case with 1 Finsbury Avenue, a prestigious and sustainable office address and cornerstone of the commercial district of Broadgate. This campus style building situated at the centre of London’s financial, cultural and creative areas aimed high with ultra-low carbon aspirations from the outset.

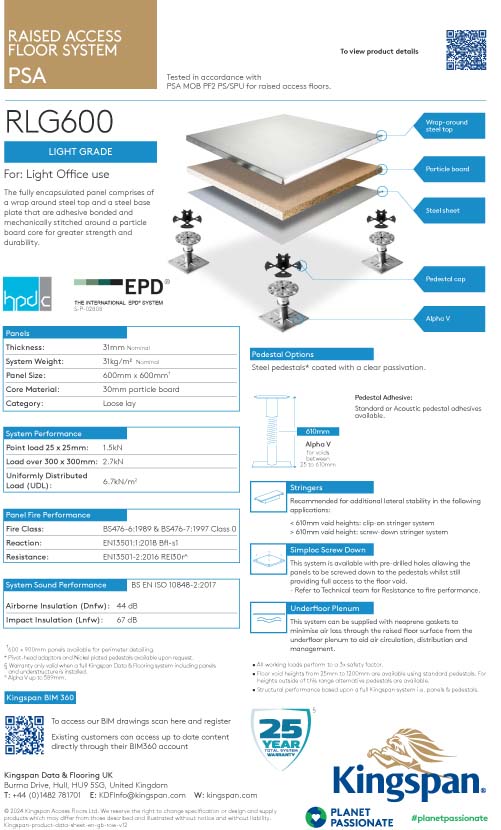

Our raised access flooring product RMG600, which was used in this project, contains up to 75% nominal recycled content without compromising longevity. We offer a full 25 year warranty assurance on every PSA grade flooring system.

Ultra Low Carbon Building

Originally completed in 1984, the Grade II Listed building was for many years home to the Royal Bank of Scotland (RBS), but after three decades of constant use, had started to look dated. So, in 2015, owners British Land decided to completely refurbish the building to restore the original façade and bring it into line with modern performance standards.

The building features myriad of energy efficiency, water saving, and waste reducing practices at every stage of construction from manufacturing to on-site fit-out, resulting in an ultra low carbon project.

Along with numerous sustainability awards for this Allford Hall Monaghan Morris designed building since opening in July 2019, 1 Finsbury Avenue won the New London Award for Conserving, given by New London Architecture for the restoration and reuse of buildings in any sector where efficient use is made of existing fabric and embodied energy.

Eco Loving

Energy efficient, water saving, waste reducing, ecologically friendly. Like all of our recent projects, 1 Finsbury Avenue was designed and managed to the highest sustainability standards. Good for people and planet.

As a global leader in the manufacturing of high performing raised access floor solutions, we continue to focus on accelerating a net zero emissions future. Saving energy and reducing carbon is at the very heart of the products we make, how we run our business and the projects we supply and fit our access flooring systems into, including 1 Finsbury Avenue.

Sequence of Trades

1 Finsbury Avenue has a total floor space of 23,000 sq. m. over seven levels, and features our access flooring system using RMG600. Although this is a significantly sized building, Kingspan Access Floors regularly completes projects of this size and greater.

However, experience has taught us that getting the timing and sequence of the different trades correct is essential when delivering a scheme like this on time and on budget.

Without careful planning, different tradespeople end up working on top of each other, and that can seriously hinder a major construction project.

Thankfully, main contractor McAlpine was fastidious in its planning and got the sequence right. The raised access floors were to be fitted towards the end of the project when most of trades had left the site, which was great news for our floor fitting teams.

Christmas Deadline

Our floor fitting teams entered 1 Finsbury Avenue in early October 2018, with the strict instruction to be completed by Christmas.

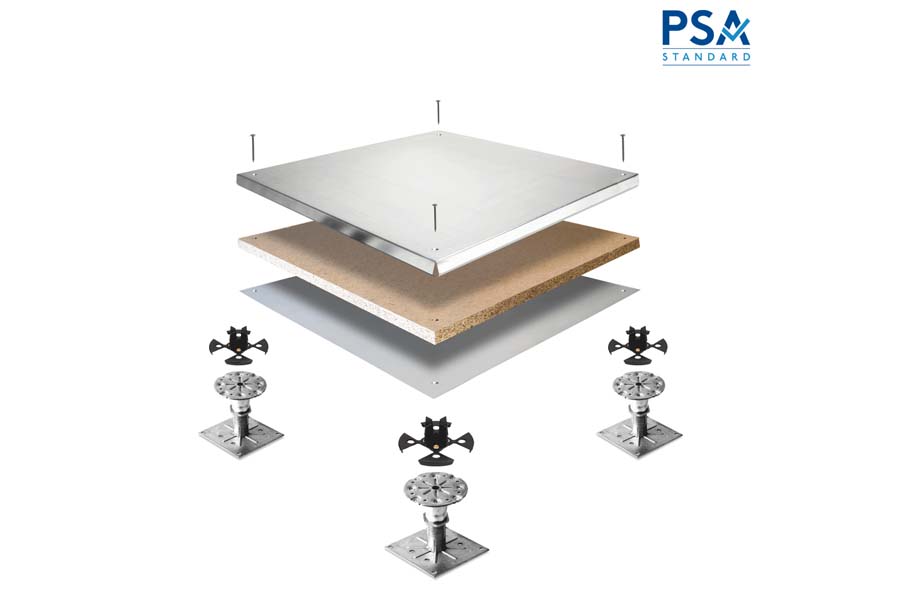

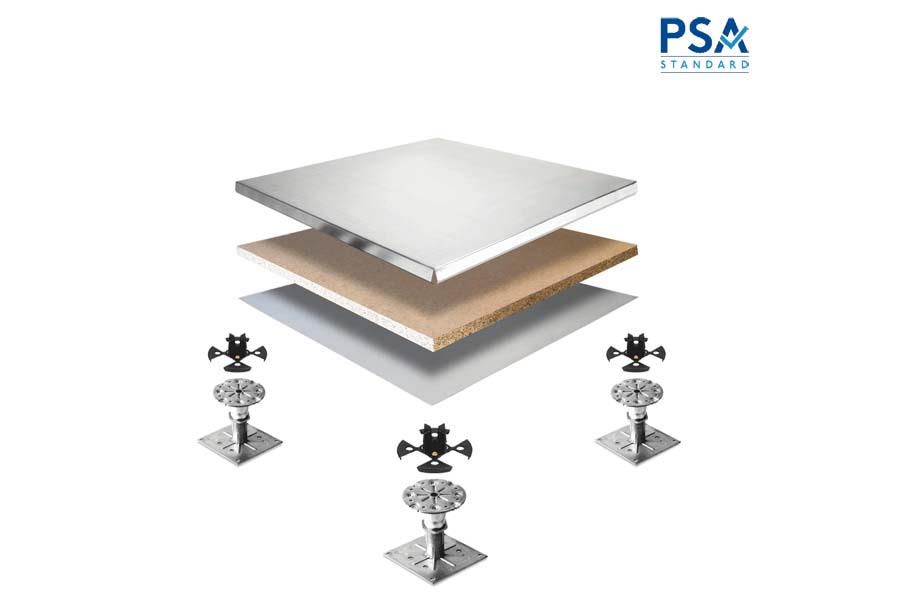

This gave us just three months to complete a job we would normally require five to six months to do. Every level of the building needed new raised access floors with a reduced floor void of 150mm, down from 500mm as the HVAC units had been moved from under the floors to the ceiling as part of the refurb.

Sound Damping Adhesive

Our teams worked exceptionally hard fitting our PSA MOB PF2 PS/SPU Medium Grade RMG600 panels throughout the building in double quick time. And to absolutely ensure we met the deadline, we brought in extra fitters so we could work on multiple floors simultaneously.

As the office building was being brought up to modern standards, we also used a special adhesive on the pedestals to reduce noise levels between each floor.

The adhesive contains granulated cork which muffles the sound of footsteps and other noises from above, creating an improved working environment with less disturbances.

Tight Deadline, But We Made It

Although the deadline was tight, our floor fitting teams laid the last raised access floor panel in time. They did us proud by completing it on time, on budget and to the high standard we stake our reputation on.

Jim Leonard, our Contracts Manager on the project, said Kingspan Access Floors pulled out all the stops to get the job done.

“We’re contracted to many jobs of this size and type but rarely with such a tight deadline,” he said.

“But that is what the client needed so we did everything possible to achieve it.

“It was a fantastic job and we were extremely proud of our floor fitting teams who really went the extra mile to complete it on time.”