Roofing underlay is installed under the exterior components of a roof, such as tiles or slate, and is designed to act as a secondary barrier against moisture in the roof space, as well as functioning in other ways to provide a weathertight roofing structure. In this article Hambleside Danelaw go back to basics to explain why underlays are a vital part of building construction.

What is a Roof Tile Underlay?

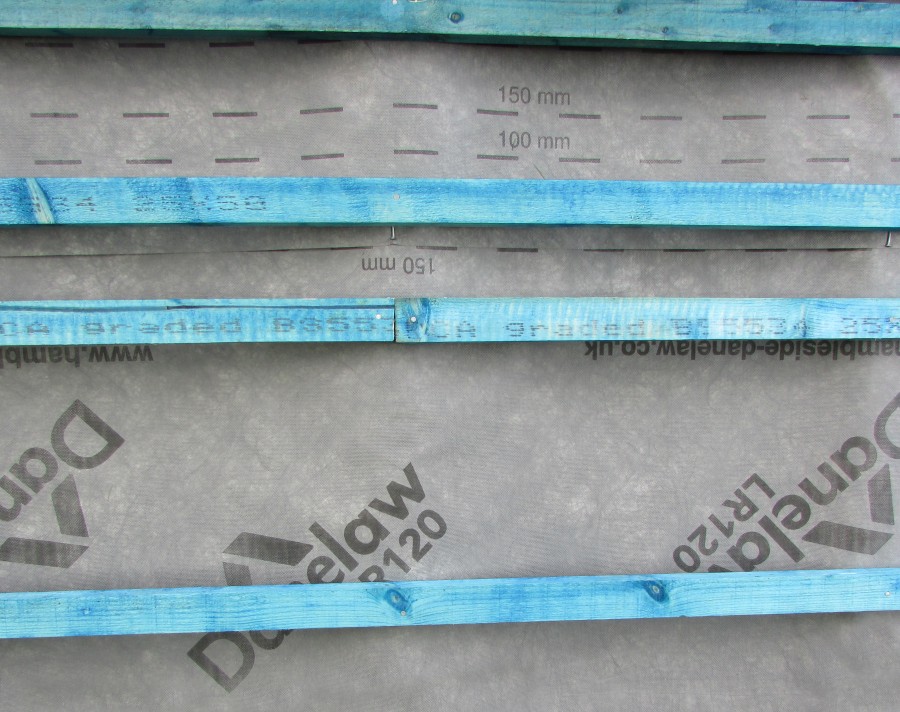

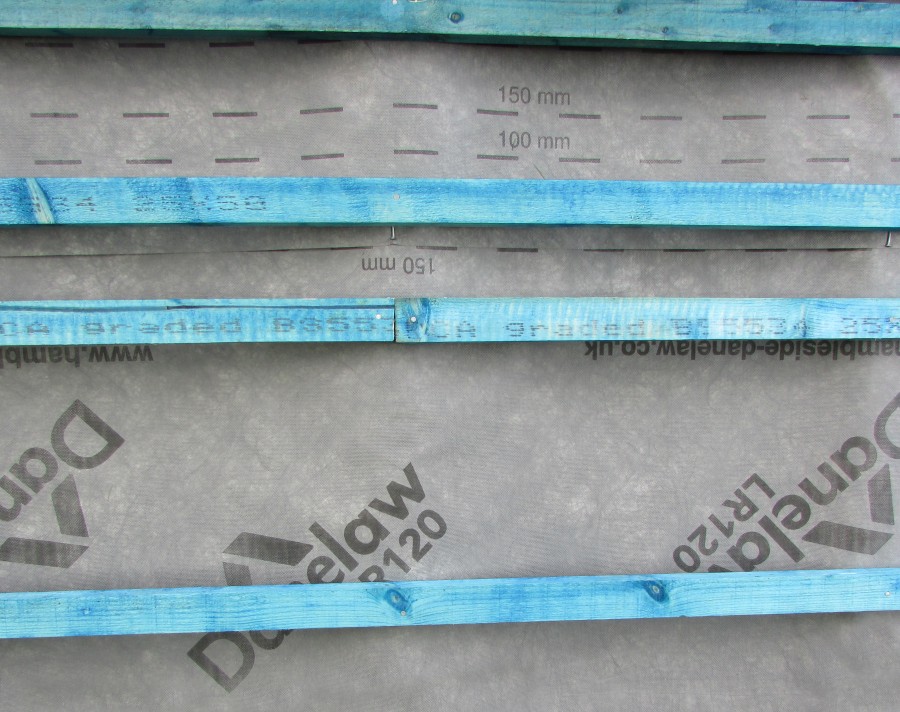

Danelaw Low Resistance (LR) underlays are fabrics manufactured in three layers. The three layers are as follows:

- Top layer is UV stabilised polypropylene to protect against the sun during installation and is usually the strongest of the layers.

- The middle layer is a microporous film which is water resistant and vapour permeable.

- The bottom layer is also made from polypropylene but is thinner than the top layer due to not needing the UV protection.

These layers contribute to the strength and weight of the product. Typically, the heavier the weight of the underlay, the stronger it is, although this can depend on the actual composition. They are also easier and quicker to lay with the right amount of drape. This drape allows any rain ingress or condensate to drain safely down to the eaves avoiding the batten nailing positions on the rafters.

LR underlays are vapour permeable and airtight, having a vapour resistance below 0.25 MNs/g (Mega Newtons Seconds per gram). There are also High Resistance (HR) underlays, classified in BS 5250 Management of moisture in buildings. Code of practice as not being vapour permeable with a vapour resistance value above 0.25 MNs/g.

The Function of Roof Tile Underlays

In addition to the secondary barrier function, one of the functions of a roof tile underlay is to reduce the loading on the underside of the slates or tiles created in part by increased internal air pressures in windy conditions.

A roof will also experience both positive and negative or suction pressures, usually referred to as wind uplift across different parts of the roof depending upon the roof geometry and pitch.

The selection of the underlay should suit the expected wind loads created by resisting a ‘ballooning’ effect and transferring the load onto the underside of the slates or tiles, therefore in locations that experience higher wind conditions, a stronger fabric is usually required.

The wind resistance performance of all rolls of underlay should be clearly identified on the label in accordance with BS 5534 Slating and tiling for pitched roofs and vertical cladding. Code of practice allowing the user to determine the suitability of the product for the application.

Wind Zones

BRE have produced a map which recognises the differing wind zone areas across the UK. The map identifies five wind zones; and underlay used in each area must be tested to show that it is suitable for the zone’s wind uplift and air pressure. The product labelling should show the wind zone suitability along with the limiting criteria for the building along with the actual wind resistance figures for the product.

All horizontal overlaps in the underlay installation should be restrained to prevent the lap opening in windy conditions. This may be either coinciding the overlap with a tile or slate batten or using an adhesive tape in the overlap.

More About Hambleside Danelaw’s LR Underlay

Hambleside Danelaw can deliver a CPD that goes in-depth into the functions of and regulations relating to roof tile underlays. To organise a CPD, get in touch with us at marketing@hambleside-danelaw.co.uk.

We also have a dedicated email for all technical enquiries at

techelp@hambleside-danelaw.co.uk.