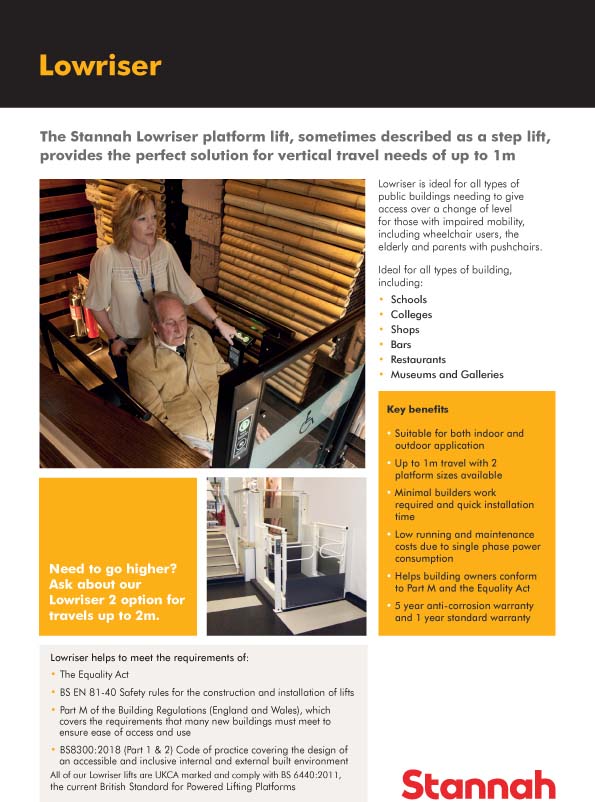

The

problem of holding a piece of insulation with one hand while wrestling with a

pair of kitchen scissors or a Stanley knife with the other is an issue faced by

many installers, according to insulation specialist Actis.

But it

says that there is a way around this problem which only costs few pounds –

money soon recouped by doing the job more quickly than with a non-product

specific utensil.

The Actis

cutter (there’s a clue in the name) may seem at first glance like an

unnecessary brand specific add-on, unnecessary to the tradesman who is the

proud owner of a box full of shiny tools.

But those

who’ve tried it say it really does make the job quicker and easier – and cuts

down on swearing to boot.

The clever

part is that the cutter keeps the insulation ‘pinched’ during the chopping

process for better and speedier cutting.

Actis

regional sales director for the South East, Steven Ellis, is a huge fan of the

device. And no, not because he gets a bonus for selling more of them, but

because he has customers who’ve told him that while they haven’t exactly

transformed their lives, they’ve certainly made them a bit easier!

A piece of

adjustable plastic on the tool ‘pinches’ the material and can be moved up or

down to suit the thickness of the product, meaning the second hand can

concentrate on just holding the material rather than wishing it had a third

hand to help out.

“If you

were to cut the material with anything else, one hand is trying to hold the

material as taut as possible and ensuring all layers stay together, while

attempting to cut accurately with your other hand. This can be time consuming,”

explained Steven, a great one for a straightforward life.

“Tricky

areas such as doors and windows, where you will need accurate and

straight-angled cuts are made a lot easier and faster with the tool as it

pinches and holds the product for you. Ultimately, it increases the ease and

speed of installation.”

Steven

says he meets many people who are quite happy using other tools though – even

though he’s sure they’d be converted if they gave the cutter a whirl.

“Generally,

they will measure out the HControl Hybrid needed and then lay this on the floor

and try and cut it with a Stanley knife or a sharp pair of scissors.

Alternatively, they will staple it on the wall or roof as desired and then try

and use scissors or a knife once again. I’m sure there are specific builder

branded scissors, but I have a contractor who says he used his wife’s kitchen

scissors and they were great. Each to their own.”