Aggregate Industries’

innovative Lytag solution was the product of choice when it came to helping to

lighten the load of a new upmarket commercial build in Edinburgh city centre.

Located in the heart

of the city’s Exchange District, the £24m 2 Semple Street development has been

designed to help alleviate the Scottish Capital's chronic shortage of Grade A

office accommodation.

With an onus on energy

efficiency and superb design, the newly-opened building boasts 45,000 sq ft of

cutting-edge office and retail space, over five storeys.

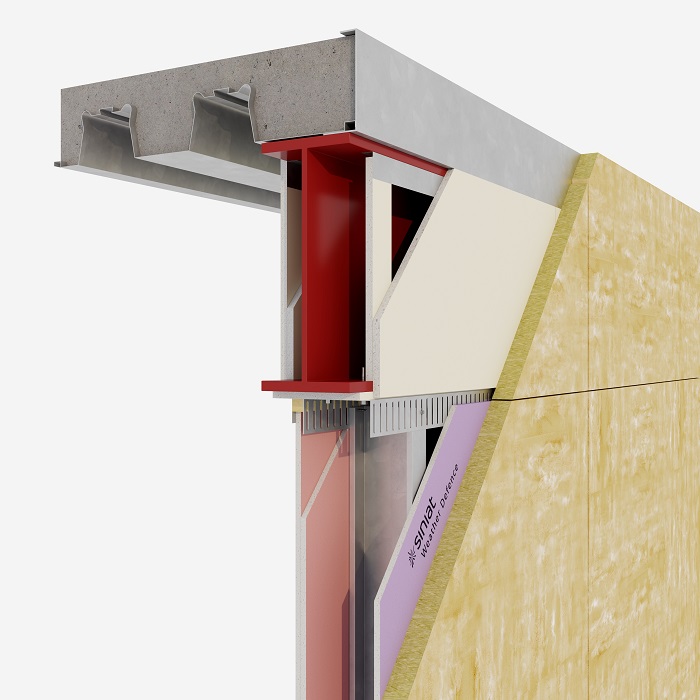

In terms of the

flooring specification the challenge for awarded concrete and screed

specialists, Advance Flooring Solutions was to procure a concrete solution

which would enable minimal size slabs and help reduce the overall dead load of

the building.

The obvious choice

then was Lytag from Aggregate industries; a highly innovative lightweight

concrete which can effectively reduce the dead load of approximately 25% over

normal weight control, while offering the same level of structural performance.

In total, 744m3 of

Lytag was supplied for the completion of the five floors over the course of

eight months. This was supported with a robust delivery framework ensuring that

all batches arrived on time and to the exact specification – thus negating the

risk of cold joints.

Stephen

McKenna, Commercial Manager at Advance Flooring Solutions said: “Lytag is a

fantastic product which was well-matched to this high calibre project for the

Scottish capital. Supported with a meticulous delivery plan, the concrete

supply was first-class from Aggregate Industries – we’d like to pass on our

thanks to all involved.”

Barry Mellor Commercial & Technical Manager for Lytag comments: “From working with Advance

Flooring Solutions at the early stages, we were able to put a stringent plan in

place to ensure a continuity and consistency of product supply, ensuring the

team had the exact specific technical and quality specification of Lytag as and

when they needed it.”

In production for more

than 50 years, Lytag secondary aggregate is made using innovative technology

which transforms fly ash into small pellets which are then heated to 1,100°C.

The pellets formed are rounded in shape and range in size from 14 mm down to

fines and can be used as a superior, consistent, lightweight aggregate.