CORNISH CONCRETE PRODUCTS HAVE DESIGNED, SUPPLIED AND

INSTALLED TWO FEATURE STAIRCASES FOR A NEW FOUR-STOREY OFFICE

BUILDING AT BP’S INTERNATIONAL CENTRE FOR BUSINESS AND TECHNOLOGY.

Designed by Scott Brownrigg,

the building was conceived from the inside out, following a

comprehensive workplace strategy to provide a modern, vibrant and

energising space to enhance collaborative working and effectiveness.

It is also adaptable to the future needs of the global corporation.

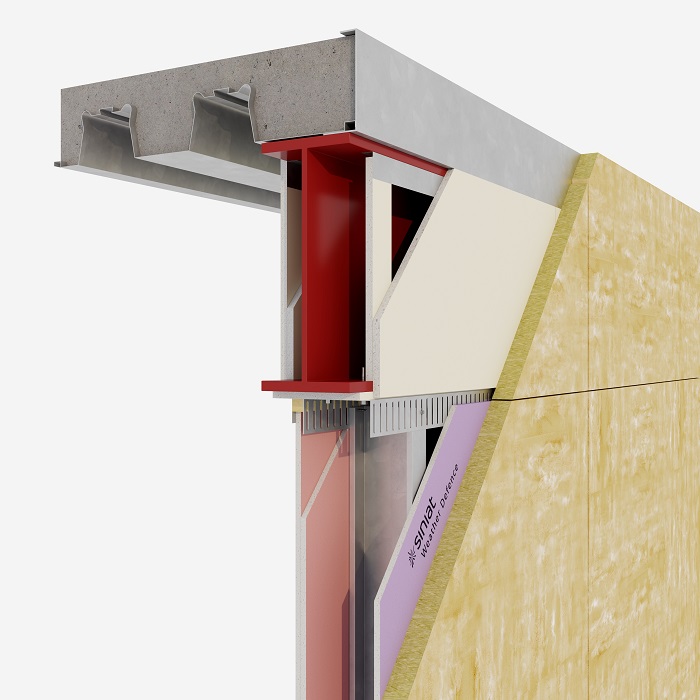

Two feature staircases are formed in high-strength

precast concrete elements connected by in-situ concrete stitches.

Large, curved, tapered spine sections are joined by prestressed

Macalloy bars and on to curved flights and half-landing units.

Working from an outline design of the staircase by

Buro Happold, Cornish Concrete Products’ engineers carried out the

detailed design of the individual precast elements and connections.

During this process, the proposed in-situ concrete solution was

switched to precast to achieve the required finish and quality. All

precast elements cantilever from the curved central spine beam which

is partly reinforced with 25mm solid steel plate.

To ensure all precast elements would fit together on

site, the curved and tapered sections were modelled in 3D using both

Solidworks and AutoCad as independent checks on compatibility.

Unlike most precast staircases, the main visual

feature was to be the curved and multi-faceted soffit and so bespoke

moulds were produced to ensure units could be cast the ‘right’

way up. Treads were rebated to ensure continuity, with in-situ

stitching of the precast elements.

The original design intent required the load to be

shared between the spine elements, which are supported on independent

foundations, and the tread units, supported from the intermediate

floors. Positive connections were therefore provided between every

tread and the corresponding spine unit.

However, as both vertical and horizontal incident

angles varied for each tread, couplers were incorporated within the

spine, welded to an embedded plate and angled to suit each tread –

a complex but necessary exercise.

All precast units included rebates, recesses and

cast-in conduit for lighting and balustrading, co-ordinated with the

reinforcement and embedded steel sections to provide the necessary

cover. The extensive liaison required during the detailed design

called for some re-analysis of the stairs to check suggested changes

to the moulds to ease fabrication and improve the final visual

appearance.

Installing the staircases was also challenging. As

the only connections to the in-situ concrete frame were the

cantilevered full landings at each storey and with all precast

components landed on props, lined and levelled, and remaining propped

until installation was complete, a detailed and comprehensive

temporary works solution was needed.

All units were stitched together in-situ and only

when the in-situ concrete had achieved the necessary strength could

the propping be sequentially dismantled.

All units were cast in a high-strength mix with white

Portland cement and white dolomite coarse and fine aggregates. Units

were then fair-faced and finally acid-etched to bring out the

attractive sparkle from the mica content of the aggregate.

The staircase was completed by adding a contrasting

inset natural stone tread and riser overlaid to conceal the

complexity of the construction underneath.