Health and safety in today’s workplace is becoming an ever increasing concern with manual handling accounting for over a third of all workplace injuries.

The majority of these injuries are caused by the handling of loads, whether lifting, lowering, pushing, pulling or carrying ("Manual Handling") The majority of advice given by the HSE and NHS to prevent manual handling injuries relates to safe lifting technique and practices, for example HSE advise people to ‘reduce the amount of stooping’ and ‘avoid lifting from floor level, especially heavy loads’, while the NHS suggests to ‘avoid bending your back when lifting’ and ‘keep the load close to the waist’.

Unfortunately, a number of everyday activities in workplaces don’t allow for these to be put into practice. One that causes many health and safety injuries, is that of removing and replacing traditional heavy metal or concrete access covers inset in the ground, which goes against all the above advice.

One company is fighting to help reduce these dangers with a highly engineered composite solution: Fibrelite first invented the composite access cover to reduce the unnecessary injuries associated with traditional metal access covers on petrol station forecourts back in 1980. The founders Trevor Pardoe and Michael Jennings had first-hand Unsafe lifting technique of heavy metal access cover experience of these in their work in the retail petroleum business.

To solve this problem, they created the world’s first composite access cover as a prototype for Esso UK (Part of Exxon Mobil). Since then, Fibrelite has continued their development of highly engineered glass reinforced plastic (GRP) access covers, maintaining the best strength to weight ratio in the industry, their covers typically weighing in at one third of metal and concrete alternatives.

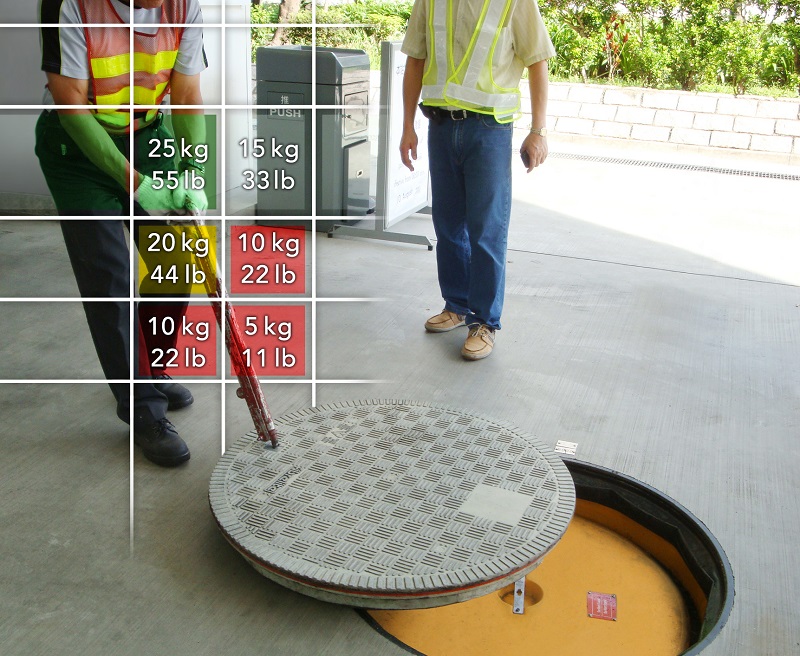

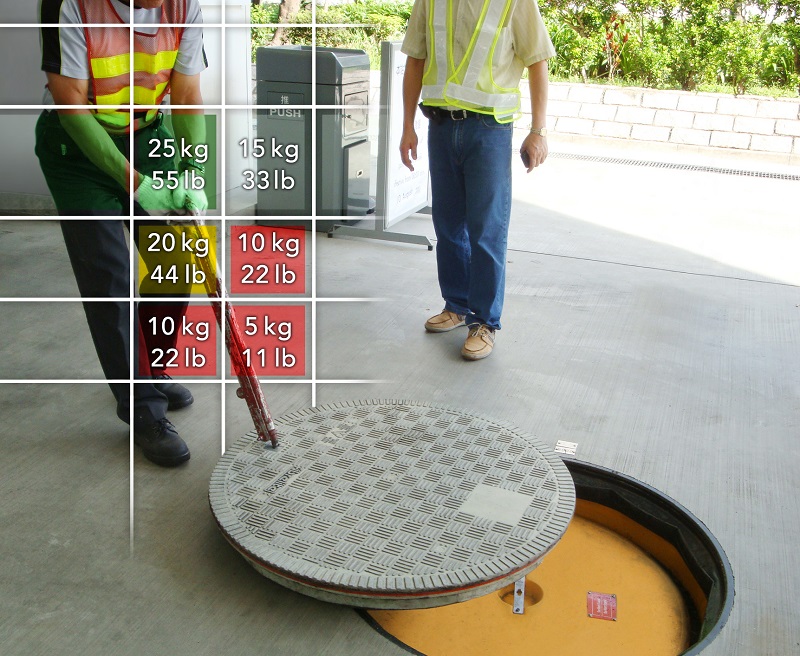

While this dramatically reduces the risk of manual handling injuries, Fibrelite wanted to find a way to eliminate them altogether. What resulted was an ergonomically designed lifting handle which slots into a keypoint in the top of the cover, allowing users to safely remove and replace the covers, while keeping the load close to the waist and avoiding stooping or bending your back, as advised by both the HSE and NHS.

Due to the light and strong qualities of their covers, even F900 (90 tonne) load rated covers can be safely lifted by two operators, whilst remaining under the advised safe lifting limit for the weight in relation to the position from the body.

Fibrelite is seeing dramatic growth in the number of industries reducing their health and safety risks by using composites, both for new build facilities where they are specified, and existing facilities retrofitting a custom cover to replace the existing.