Symphony, the UK’s leading fitted furniture manufacturer with over 40 years of heritage, has added yet another prestigious award to its collection, after being awarded Zero Waste to Landfill status.

The award, which is given to an organisation that successfully puts in place procedures to ensure no waste product goes to landfill sites, was devised with the help of Leeds Paper Recycling (LPR), a local recycling company that ensures 100 per cent of waste from Symphony’s manufacturing processes is recycled, reused or reconstituted for other purposes.

The Zero Waste to Landfill initiative represents a responsible next step in environmental stewardship, both through the effective management of byproducts and also the elimination of materials going into landfills.

On the accolade, Simon Collyns, Marketing Director, commented: “Symphony is proud of its latest achievement. We’ve worked closely with LPR to ensure that zero waste as a result of our manufacturing processes, goes into landfills. That is no mean feat when working in our industry, but thanks to our staff and partners, we have successfully put procedures into effect across all of our sites that encourage a green way of working.

“Being green is a way of life at Symphony and we are proud to be an organisation that continues to innovate our products, services and ways of doing business.”

The Zero Waste to Landfill award is the latest in a line of green credentials that Symphony is proud to have been recognised for. Symphony subscribes to the best principles of One Planet Products procurement policies and is currently the only kitchen manufacturer in the private housing market approved by One Planet Products.

Through Symphony’s demonstration of their ability to improve their environmental credentials they have become part of FIRA’s Club Green initiative2. This philosophy is reflected across Symphony’s Eko Design initiative, which means every kitchen is designed and manufactured with sustainability in mind. Symphony has also engaged with WRAP and Valpak to undertake a number of initiatives to reduce waste and minimise packaging, such as using reusable protective blankets on deliveries.

The green credentials don’t just stop there; Symphony has incorporated BREEAM standards across its head office facilities, which includes the 500,000 sq ft state-of-the-art marketing suite.

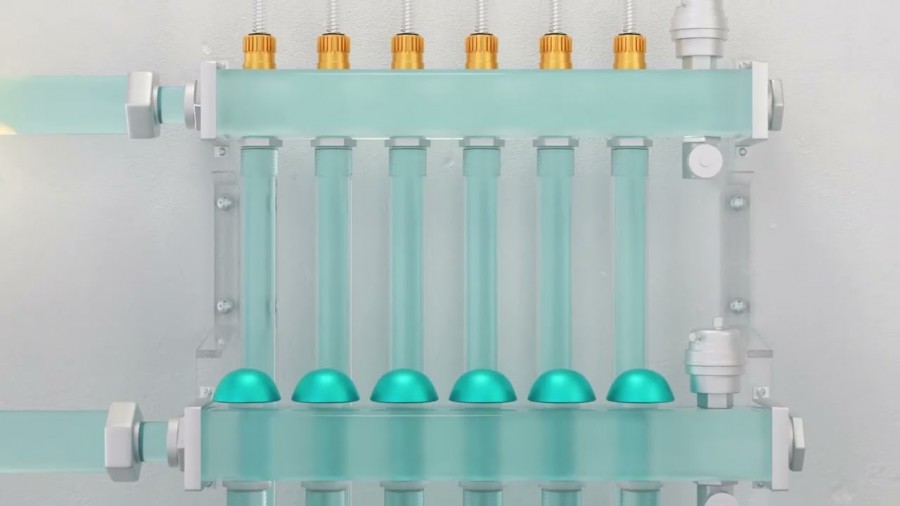

What’s more Symphony’s site contains one of the largest biomass boiler plants, which has negated the need for gas supply to the site, and there are future plans to make Symphony’s headquarter 100 per cent self-sufficient.