A new visitor centre at Stonehenge is proving to be a beacon of advanced construction design and technology - from the stunning canopy roof down to the pipework infrastructure.

As befits a building attached to a world heritage site, sustainability and environmental sensitivity have been designed into the building at every level, hence the decision to select innovative materials above and below ground.

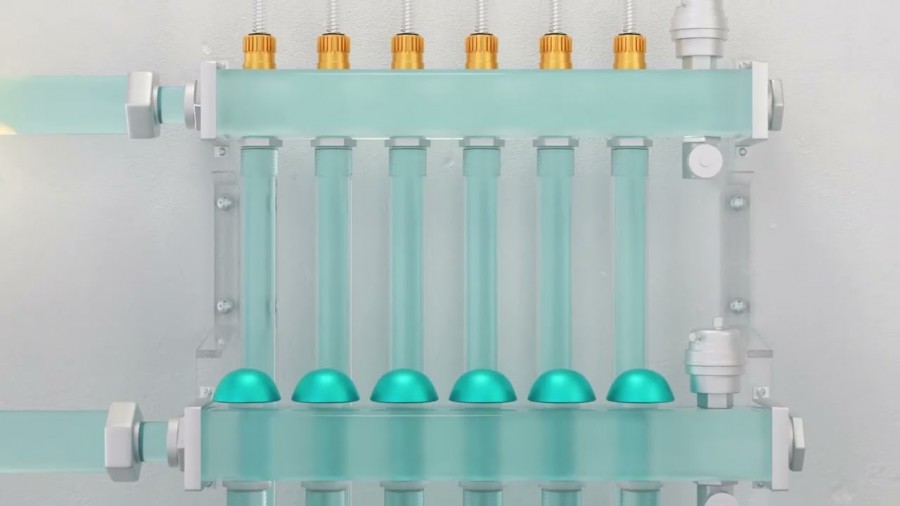

In the case of the pipe network linked to the site's ground source heating scheme, hot water and space heating, the project specifiers and pipework contractor (Spectrum HPM) turned to Flexalen technology from Flexenergy.

As Robbie McKay, Project Engineer at Bristol-based Spectrum HPM Ltd, explains: "We selected the Flexalen pipe system for this project as the Flexalen 600 pre-insulated polybutene range brought strength, flexibility, broad temperature range and strong sustainable construction credentials to the project - qualities that were critical on such a sensitive and nationally-important site." This range also offered closed cell, water-tight polyolefine thermal insulation and a homogenous connection between insulation and casing pipe as part of a fully welded system."

The laying of the pipework was closely controlled because of the rich archaeology associated with the site, with ductwork for services laid within a 2m infill of a hollow within which the building is located.

"We are very proud to be associated with such a prestigious project on a world-renowned site," said Sandy Fairley, Flexenergy Sales Director. "The pipe technology selected by Spectrum HPM for the visitor centre combines strength, durability and flexibility across a wide hot water temperature range when compared to conventional pipe. Its light weight profile also makes it easier to handle, while its HDPE outer jacket gives robustness to the structure.

"One of the biggest concerns for this project was environmental sustainability - so the pipe technology's low thermal conductivity and consequent heat loss became important factors in the context of optimising energy efficiency in a low carbon environment."

Flexalen pre-insulated pipes use Polybutene (PB-1) as the base material for their carrier pipes, and is the only plastic pipe system currently used in heating systems that can be fully fusion welded and operate up to 95°C.

The Stonehenge visitor centre sits in a shallow hollow and consists of two simple rectangular pods housing a cafe, with retail space and educational facilities plus a smaller ticket booth.