The strive for energy efficiency and sustainability can too often focus on a single quick fix or miracle solution to try and reduce the carbon emissions of a property, these headline innovations may contribute in a variety of ways but in the end the outcome is only as robust as the sum of its parts. It is in this construction as a whole that the cumulative gains of multiple elements will begin to tip the scale and is often where the benefits of those unseen and unsung products really start to make a difference.

There are several areas in which a home can be made to be more energy efficient, one of which is to ensure that once heated the building retains that heat for as long as possible to prevent more energy being used to reheat it once again. Most people would identify the solution to this as insulation, to which they are not wrong, a well-insulated house will retain radiating heat for longer. But there is another means by which heat energy can escape, that is through the loss of warm air from the property, also known as air leakage.

As housebuilders sought to limit the loss of this warm air from dwellings, numerous problem areas were identified as new build homes became subject to pressure testing once constructed. One such area being the penetration created behind radiators by modern plastic pipework, these holes not only provide an air leakage path but were also located directly behind a heat source, further compounding the energy losses. As the detail was relatively new, no bespoke solutions existed and temporary fixes using existing electrical products could often create further issues down the line. It was at this point that Manthorpe Building Products was approached by the leading UK housebuilders to create a tailor-made solution to the problem, the result of which saw the first Radiator Pipe Guide and Seal launched in 2006, closely followed by the Face-Fix seal a year later and the Single Exit a further year on.

These seals remain concealed behind the radiator, helping to not only prevent the loss of warm air through the pipe penetration, but also to guide the pipework out of the wall at the optimum angle to prevent them becoming damaged. Unless you’re looking to decorate or are overly inquisitive by nature you may never even know these products exist, let alone fully understand their function, but they have now become a standard addition to the detail and are wildly used by small scale and volume housebuilders alike.

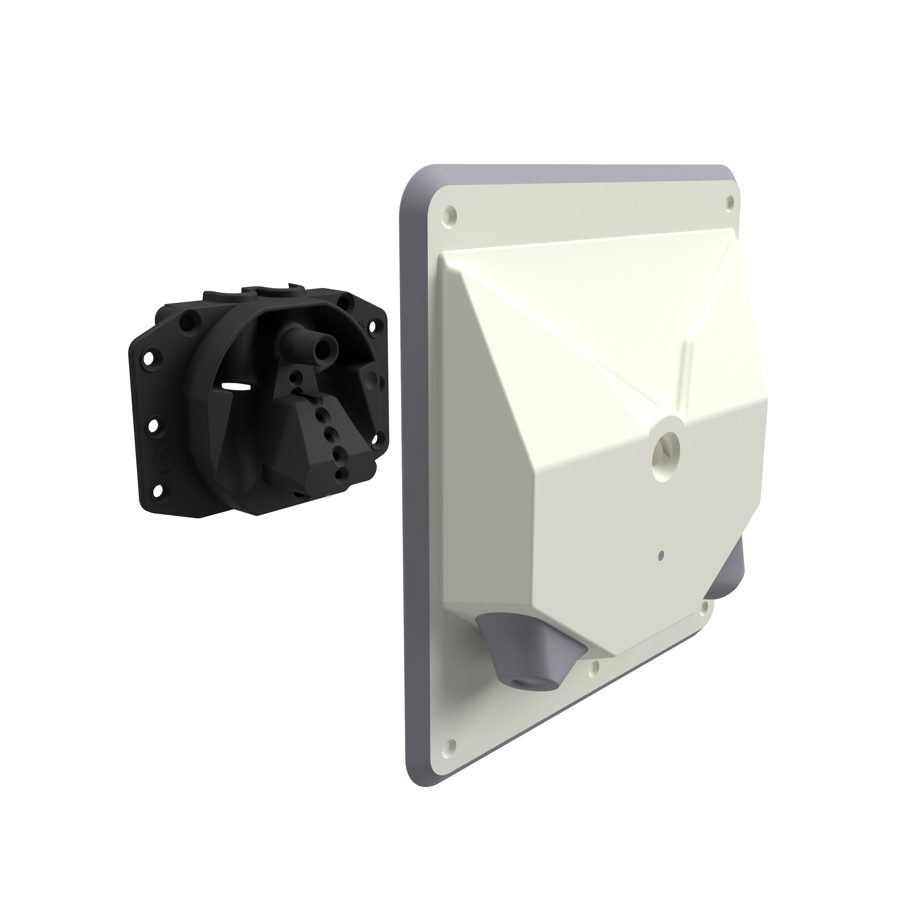

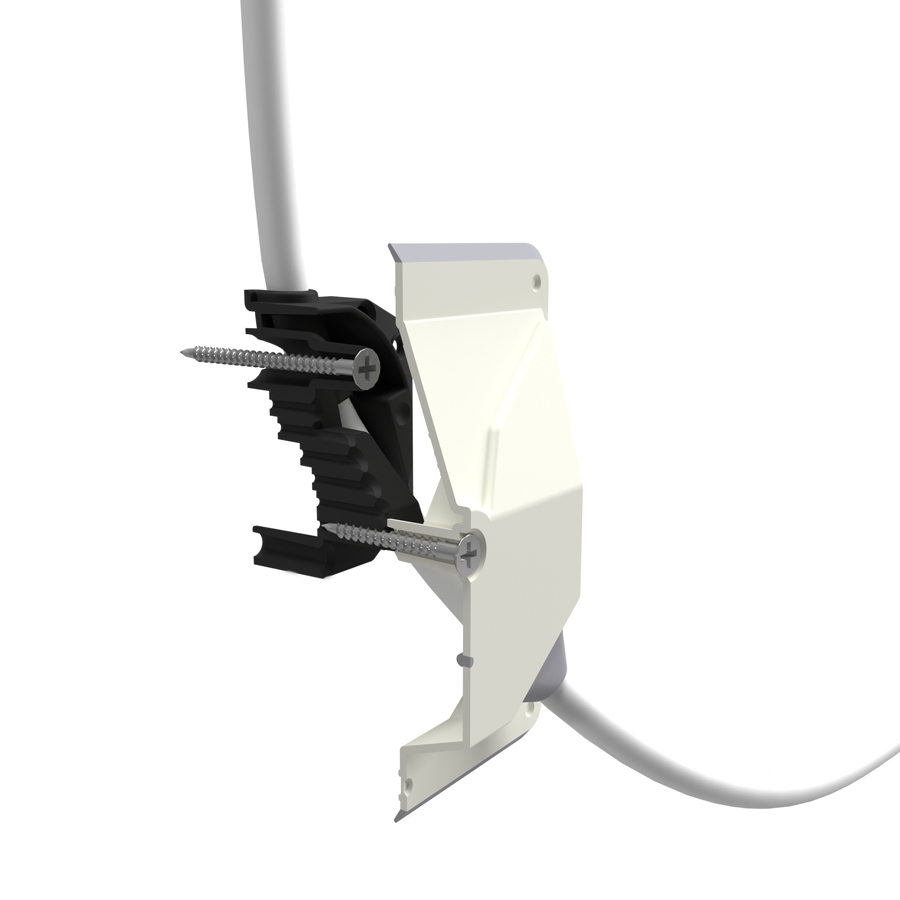

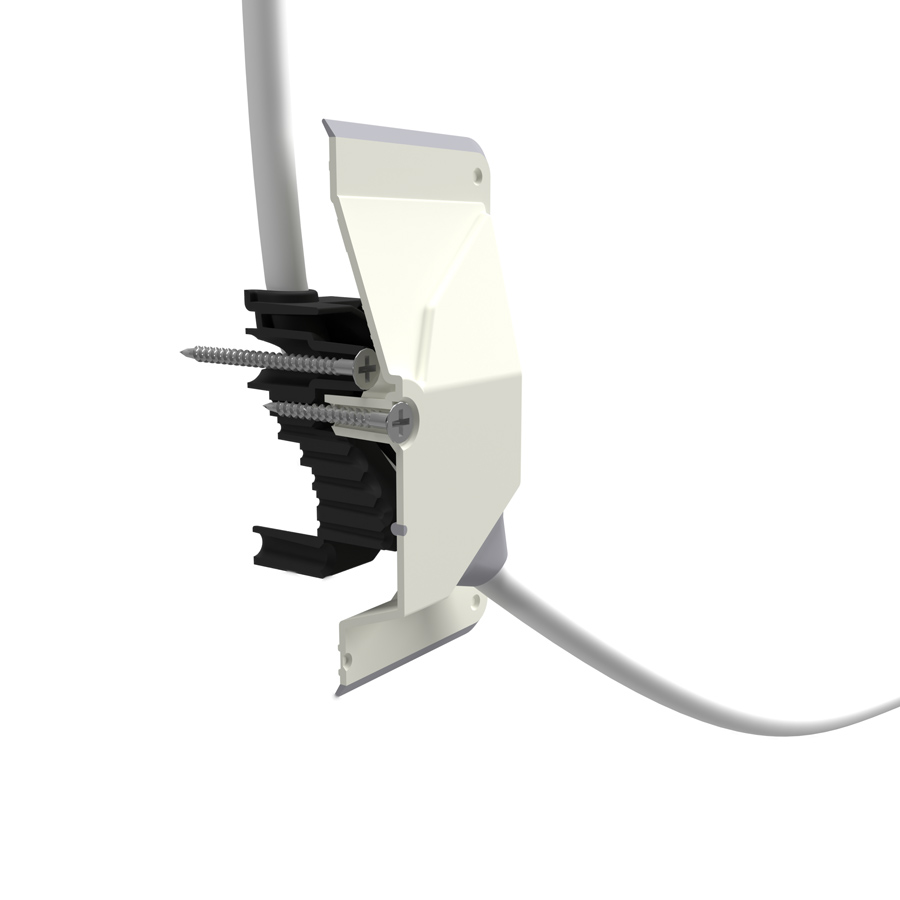

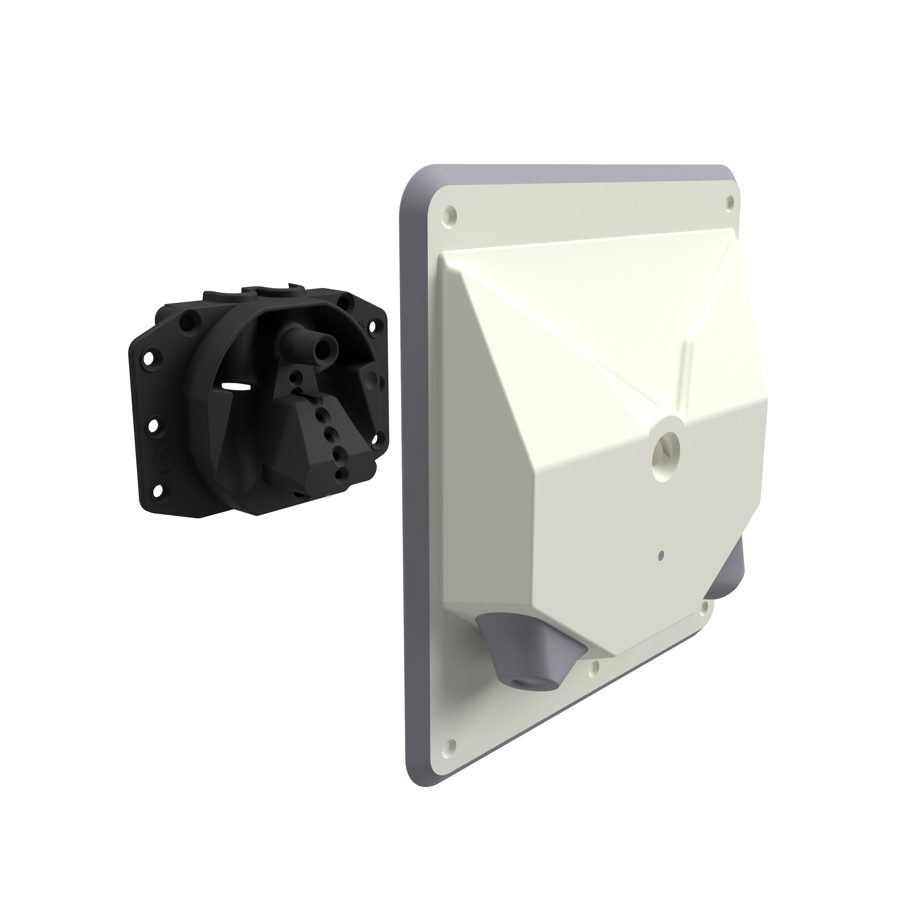

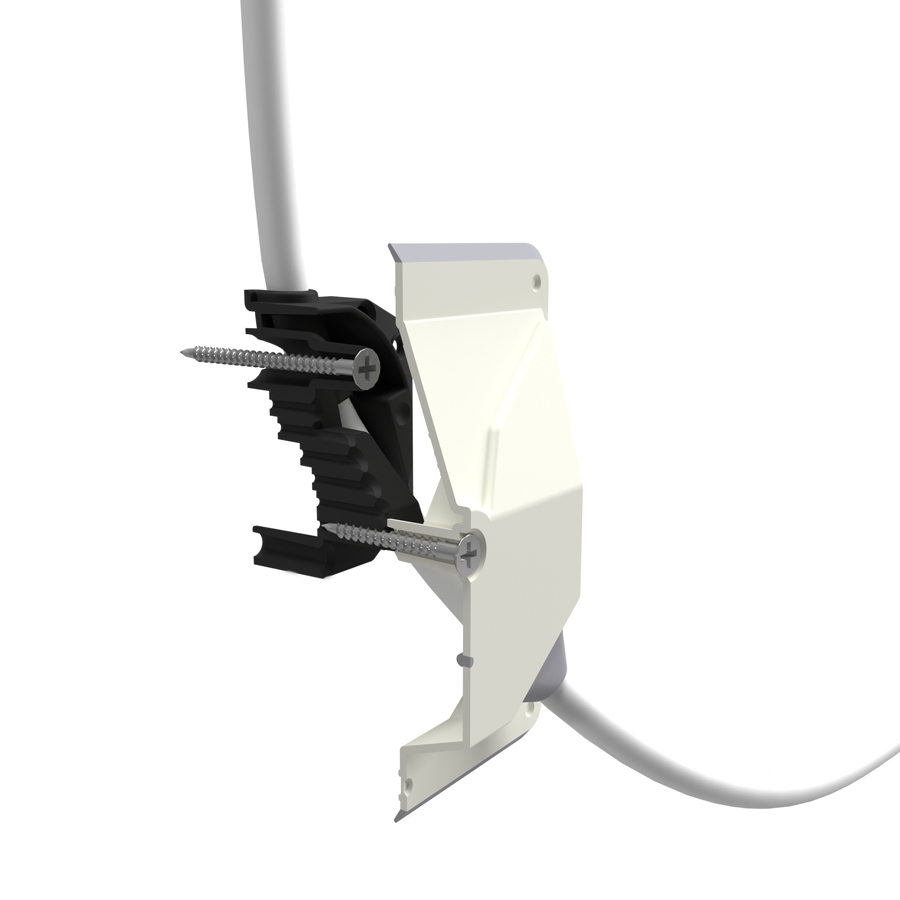

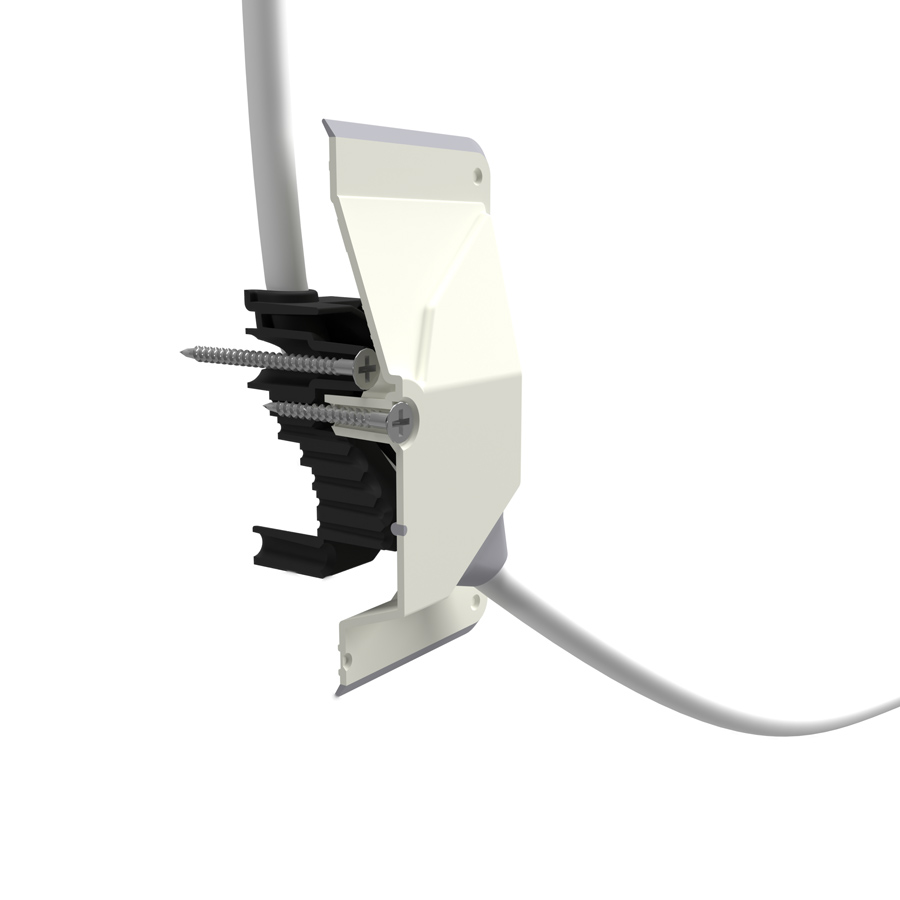

The time has now come however for the next generation of Pipe Guide & Seal to take over. Building on the legacy of the existing range and with over 15 years of experience to draw on, Manthorpe has created the GRS-DUO, an innovative “twin plate” system which sees both plates working in conjunction with each other, each specifically tailored to meet the needs of both the first and second fix plumbing phases. The first fix Mount Plate can be easily affixed to the blockwork or stud wall construction to help clamp, align and guide the pipework through to the exact position the plumber wishes the radiator to be. The interim works such as dry lining, plastering and decorating will then be completed knowing that the pipework is kept secure and correctly oriented. The Cover Plate is then fitted during the second fix plumbing phase, sealing the pipe penetration to eliminate the air leakage path behind the radiator. The Cover Plate is secured into the Mount Plate behind with a single, central fixing, no more unreliable plasterboard fixings needed, with the two plates being able to accommodate a variety of plasterboard and radiator bracket offsets in use.

The new GRS-DUO adds another layer to the unseen work that Radiator Pipe Guides & Seals do within the construction of a home; offering improved positioning and fixing versatility along with a more robust seal to further ensure that air leakage behind every radiator is eliminated, with each discreet installation helping to limit those thermal losses in the building.

Ben Hales

Product Designer, Manthorpe Building Products